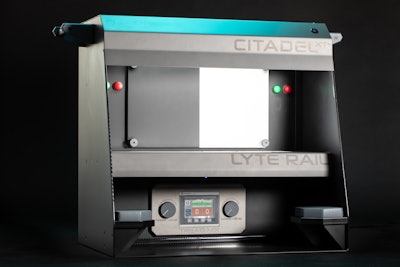

At PACK EXPO, Quantum Packaging Technologies showcased its Citadel XT+ manual inspection hood for visual inspection of pharmaceuticals, devices, and drug delivery products.

Featuring manual lighting intensity adjustment, the standalone XT+ gives inspectors ease of use with manual light settings coupled with the company’s TREAD MX PLC-controlled pacing console with password protected recipes and traceability.

Explains Quantum’s Scott Smith, “What we’re doing differently in the industry is we're using a higher frequency, full-spectrum LED lamp. For the most part, the industry is still using fluorescent tubes today, as well as some LED but more on the NIR spectrum—more of a red color. We’re lean more on blue-green side, which is the easier on the eye and less of a sharp spectral spike that you'd get from fluorescent lights and better for contrast.”

When operators inspect vials looking for particulate matter, fluorescent lamps flickering lights can cause them to experience a vertigo effect or get tired and need a break. Says Smith, “Because these LEDs emit light so quickly, they're truly flicker-free, which is easier on the operators,” he notes.

Quantum employs several technologies to eliminate glare during inspection. “We use a firearms coating on the hood, same as what’s used by the U.S. Navy. For pharmaceuticals, it works really well because it's anti-reflective, anti-glare, and corrosion-resistant. We do a lot of things to mitigate glare, including using a diopter system with nanocoating which is also anti-glare, and the whole entire hood is sprayed with a Polymer Derived Ceramic Compound. Cerakote comes in multiple colors so pharmaceutical companies can get a customized look on their equipment.”

The Citadel also uses a unique pacing system. “Most people typically use a proximity sensor. We try to avoid that. We use a [light curtain] system, making it more poka-yoke for the operators—they can’t cheat it,” Smith adds. The system also features cooling fans and antimicrobial/alcohol-resistant memory foam arm rests for the operators.