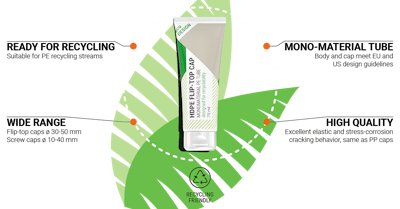

Hoffmann Neopac, a provider of high-quality packaging for a broad array of industries and applications, has introduced the market’s first fully recyclable polyethylene-based tubes with high-density polyethylene (HDPE) flip-top caps. The mono-material tube + cap combination is designed to overcome a longstanding functionality hurdle for hinged caps, which were previously made predominantly from less recyclable polypropylene (PP) materials.

These tube systems are a packaging first: fully recyclable tube systems whose body, shoulder, and caps are composed of a single material family. Also available in screw-top formats, the tubes are made for health & beauty, food, and pharma packaging applications.

In existing recycling streams, mono-material plastic packaging is preferable to combination plastics, as it is considered fully recyclable in mechanical recycling plants and therefore a key factor in moving toward a truly circular packaging landscape.

In addition to the new HDPE flip-top caps, Neopac is also launching a comprehensive portfolio of PE screw caps. Manufactured in-house, the screw caps are available in diameters of 16-40mm. These are designed to form functional closures from the same material as the tube body and shoulder.

The full PE Cap range is commercially available for all Neopac’s PE, COEX, EcoDesign, or Polyfoil Range. Starting November 2020, the recyclable mono-material PE Tubes with Flip-top cap will be available as stock systems with the printing service DigitAll360°.

Looking ahead, Neopac is currently in the development stages of next-generation, HDPE-optimized high-performance barrier tubes (Polyfoil® MMB) with superior decoration options. Available with PE screw-top caps, the forthcoming systems have received positive ratings from Institute Cyclos-HTP, a packaging recyclability certification organization.