Entrepreneur Anita Redd has found a successful niche in the skincare business by introducing products and packaging born of necessity. The Anita’s Balm product, launched in 2011 to sooth and prevent dry skin resulting from eczema, was originally formulated by Redd in her kitchen as a natural remedy to ease the suffering of her son, born with a severe case of eczema. Today, Anita’s Balm, Inc., of Lawrenceville, GA, offers a number of products, including hair, lip, and eye balm, along with its original skincare formulation.

In 2013, when Redd learned the packaging for her roll-on balm would no longer be available, she again took matters into her own hands, researching and designing a new container that met her aesthetic requirements while using a more sustainable packaging material. In December of that year, Anita’s Balm launched its roll-on product in a 1-oz compostable twist-up container in the shape of a tiny amphora jar that is manufactured by Redd and her husband using a 3D printer and polylactic acid resin.

“It’s the only one like it on the planet,” says Redd of the patent-pending container. “We were determined to innovate and change packaging options. We did not want to accept the status quo; we wanted to do what had not yet been done.”

Hands-on product, pack development

Anita’s Balm is an all-natural product containing just two ingredients: cold-pressed olive oil and natural beeswax. Redd came up with the recipe when she noticed that olive oil offered a natural, dye-, fragrance-, and alcohol-free alternative to the moisturizers currently on the market. Redd then added beeswax to solidify and stabilize the oil, making it easy to apply. “The mix worked well for my son and was very convenient, so I told people about it, and they started asking for it,” says Redd.

Since being launched for retail sale, the product has won the attention of major retailers and distributors, such as Whole Foods, Smith Drug, Cardinal, AmerisourceBergen, and McKesson. More interesting though, relates Redd, is the range of other businesses that have expressed interest in the product line, including long-term care facilities, spas, pet grooming salons (for dry or cracked paws), holistic birth centers (for stretch marks, breast cracks, diaper rash, and cradle cap), sporting goods stores, and even tattoo parlors. “Basically, anyone with dry or irritated skin can find rapid relief with this product,” she says. “The possibilities are virtually endless.”

The products are currently sold in natural food stores and pharmacies nationwide as well as on the Anita’s Balm website. Products include original-formula balm in a 4-oz jar, lip balm in a 0.015-oz tube, hair balm in a 2-oz bottle, and eye balm in a 0.13-oz applicator. Until recently, the company also offered its original formula balm in a 1-oz cylindrical, roll-on container made from polypropylene. When the stock package was discontinued, Redd bought up what was available and began looking for a replacement.

For the new package, Redd was searching for a twist-up container in the shape of a jar. “Our balm is intended to moisturize dry skin and works best when applied directly to the affected area. So a twist-up tube had been our best seller,” she says. “I wanted to continue that applicator in a more attractive and biodegradable container.”

Redd explains that using renewable PLA resin made from corn or sugarcane for the new package was important to her, given her sustainable approach to life: “I buy refillable coffee cups, recycle extensively, participate in co-housing, which utilizes solar energy, etc. I wanted to extend that philosophy to my containers. Rather than having them end up in landfills or floating in ocean gyres, I prefer they decompose. Also, it is a good business decision; there are a lot of consumers interested in products that are good for the environment.”

But Redd’s search for a supplier that could meet her packaging specifications was unsuccessful, so she pursued technology on her own that would allow her to create such a container in-house. “Despite the challenges of working with PLA, I was determined to overcome these and make our container out of it,” she recalls.

3D printing ticks all the boxes

In researching viable equipment for manufacturing her roll-on container in-house, Redd discovered the potential of 3D printing and purchased a MakerGear M2 3D desktop printer. The technology offers the control, design flexibility, and material opportunities Redd was seeking.

The first step in creating the new package was the structural design, which was guided by Redd and engineered by her husband, Jason, through AutoCAD drawings. The 1-oz container features an intricate design, with a full, round body and decorative handles on either side, giving it the appearance of an ancient amphora jar. In the front, a round concave area accommodates a pressure-sensitive label, while the back of the jar features a square, convex space for another label. Under each handle is an embossed flower design that is repeated across the bottom of the jar in a filigree style. A screw-on cap is decorated with a crisscross design, while the bottom of the jar twists to push up the roll-on balm. The entire surface of the jar offers a subtle, lined texture.

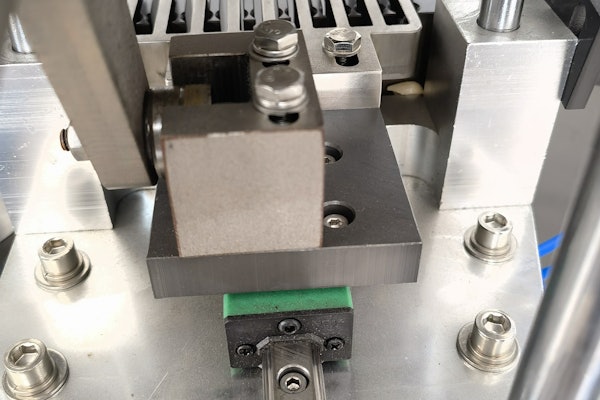

To produce the plastic filament used by the 3D printer to create the package, Anita’s Balm installed a Lyman-type extruder, built from a kit from Filastruder. The company purchases PLA pellet from Industrial Hobbies, which it mixes with white colorant and extrudes into filament. “This is very cost-effective over buying prepared filament at thirty dollars-plus per kilo,” explains Redd. “Extruding the filament and getting a good price on the pellets, plus not paying shipping from a supplier, allows us to produce this jar for a very good price.” Constructed of PLA, the jar is compostable in industrial facilities, per ISO, ASTM, and EN regulations.

Decoration of the jar consists of four pressure-sensitive vinyl labels, including a 5/8-in.-dia label on the front with the Anita’s Balm logo; a 1 3/8 x 5/8-in. label on the back, containing ingredient information; a 1.5-in.-dia label for the top of the closure, which features the brand name, product benefits, and company website; and a 1? x 3/8-in. UPC label for the bottom of the jar. Labels are printed and die-cut by Fast Signs.

During package manufacturing, a set of codes is sent to the 3D printer that directs the machine to lay down successive layers of molten plastic at a certain thickness, height, and shape, until the part is complete. The balm jar is made up of five components—the body, the closure, the base to hold the balm, the bottom, and a hex nut—each of which is printed separately. Redd says that by using the 3D-printing process, the five components can be produced, and the jar can be manually assembled, filled with balm, labeled, and sealed with a tamper-evident band supplied by Uline within a few hours.

“We have much more control over the whole process, from the plastic we choose, to the color we make, etc., and we can mail them out immediately—no waiting for shipping from a supplier or dealing with backorders and discontinuations.”

The process also provides Anita’s Balm with flexibility to tweak its container design, without additional costs. Says Redd, “We can control the hollowness by using the settings on the 3D printer and create a light but very strong jar. We can revise the design relatively easily and inexpensively, and the price of the printer is low compared to purchasing traditional manufacturing machines.”

Redd also says she loves the ridges and textures made possible with 3D printing, as well as the design enabled by PLA. By all accounts, so do consumers, she notes. The first batch of 150 1-oz jars printed by Anita’s Balm sold out within weeks. As Redd shares, “Environmentally conscious and health-oriented stores have been very favorable toward the jars.”