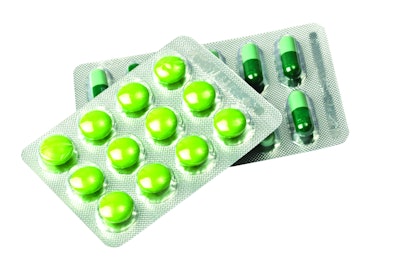

Tekni-Plex, Inc. introduces a new sustainable blister film alternatives to films containing PVC—the PX and PXA Series of materials available in all standard thicknesses and combinations.

PX and PXA Series of films provide equivalent performance, enhanced processability, and increased clarity when compared to PVC multi-structured laminated barrier (duplex and triplex series) and monoblister films. The cost-effective films are suitable for applications including pharmaceutical, medical, nutraceutical, food, and health and beauty accessories.

PX is non-barrier copolyester, which serves as an alternative to monolayer PVC for packaging applications that do not require any particular barrier properties. PXA is a laminate of co-polyester and PCTFE films (Aclar®* or VapoShield™) for blister packaging applications that require protection against moisture ingress or egress. Traditionally, these products have been packaged in PVC/PCTFE or PVC/PE/PCTFE laminations.

The PX and PXA Series offer excellent clarity and transparency properties, and are compliant with EU and FDA regulations for direct contact to pharmaceutical products. The materials are sealable with all conventional blister lidding (push-through, peelable, CR), exhibit the same barrier performance as conventional barrier solutions, and enjoy excellent performance during perforation and punching.

The Tekni-Plex PX and PXA Series are easier on machines and the environment regarding energy use. Both films run well on all form/fill/seal equipment—including high-speed lines—and easily form into standard tablet and capsule designs as well as more complicated blister cavities. The films are compatible with all Tekni-Films and other commercial lidding structures designed for sealing to PVC, with no changes necessary to the thermoforming unit and tooling design. Films form at lower temperatures than conventional PVC-based films, an energy-saving and cost-reducing value added feature.