Werum IT Solutions has released the latest version of its PAS-X Manufacturing Execution System (MES) for the pharmaceutical and biopharmaceutical industries. The new PAS-X 3.1.8 features several improvements for efficient manufacturing based on the latest technology standards. PAS-X 3.1.8 not only facilitates regulatory compliance, but also supports drug makers to ensure high quality in their manufacturing processes.

The latest trends in pharmaceutical manufacturing have been considered and reflected in the new PAS-X. The company’s user forum PAS-X For Us actively participated in advancing PAS-X 3.1.8.

The use of PAS-X as an MES ensures data integrity and significantly reduces possible data integrity related issues. Together with the PAS-X For Us working group the MES-related data integrity positions of the pharma & biotech MES user community are defined.

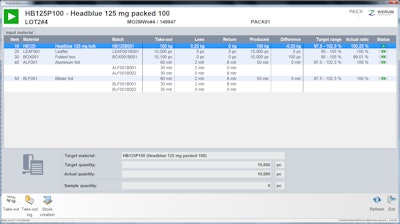

Werum continues its usability initiative with a particular focus on quality in shop floor operations. With PAS-X 3.1.8, the most important material-related functions can now be accessed more easily and have been given an optimized user interface. Werum also introduced a dedicated dialog for material reconciliation with built-in best practices. The new automated material flow overview allows the operator to control the quantities that have been consumed and processed.

PAS-X customers will benefit from the reduced downtime needed to update the software version. A short downtime is crucial for modern bio-pharmaceutical manufacturing processes. Downtime has been reduced by more than 50%, according to the company.

PAS-X 3.1.8 allows a cumulative one-step MES product upgrade and data migration. It runs with the latest platform versions such as Oracle 12. Support of the new OSIsoft PI Event Frames simplifies integration of shop-floor systems.

PAS-X 3.1.8 allows an even smarter integration of Werum’s proven PAS-X solutions such as Track & Trace, KPI/OEE and the new Evaluations Package. The new PAS-X Evaluations Package helps pharma manufacturers unlock the full potential of shop floor data. In PAS-X, all production-related data and data of the interfaced IT systems converge. Supported by the integrated and web-based PAS-X Evaluations Package, this combined information can be used to make production assessments and develop strategies for process optimization.

Werum customers benefit from automated execution features such as automated material flow and automated equipment identification, each of which improve user efficiency and reduce risk of human error. Data integrity is supported by alarm & events, directly retrieving GMP-relevant exceptions also from level 2 systems and enabling QM to significantly accelerate the release process of Batch Record Reports through review by exception. Further acceleration can be achieved by auto-closure functions, which unburden QM from checking batches without any exceptions and critical parameters at all, as manual release is no longer required.

PAS-X 3.1.8 contains the experiences and best practices of decades of successful MES projects in all areas of the pharma and biotech industries. Several Werum customers have already decided to incorporate PAS-X 3.1.8.