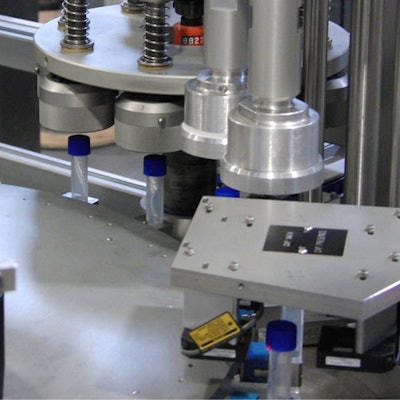

• servo-driven cap placement and torque systems are featured on the company's next-generation monoblock filler/capper

• operate at speeds up to 120 bottles/min; design allows precision cap handling to reduce risk of dropped or skewed caps

• two-stage torque system first uses a unique “donut” clamp to place the cap with accuracy and applies the first level of torque to secure the cap; final torque is applied at the second stage

ESS Technologies, Inc.

• operate at speeds up to 120 bottles/min; design allows precision cap handling to reduce risk of dropped or skewed caps

• two-stage torque system first uses a unique “donut” clamp to place the cap with accuracy and applies the first level of torque to secure the cap; final torque is applied at the second stage

ESS Technologies, Inc.

Companies in this press-release