This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

TurboFil Packaging Machines' assembly and vial filling machine for unidose liquid nasal devices is available in automatic or semi-automatic setups. The company’s UDS Rotary Vial Filling & Assembly Workstation increases throughput and flexibility through its array of station separation and inspection options.

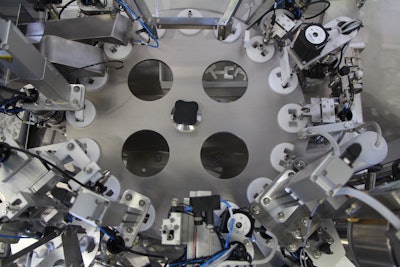

For automatic operation, a racetrack format with vibratory product feeding offers speeds up to 80 to 100 pieces per min. For semi-automatic settings, the system utilizes an operator-loaded indexing star wheel with pucks, producing up to 30 pieces per min. After using an air jet and vacuum system to clean each vial, the machine’s initial inspection station checks for cracks. To perform this step, vials are raised and rotated, allowing for 360-deg high-resolution camera inspection.

Next, vials are filled via a precision valve-less ceramic piston filler at a station incorporating a no-container/no-fill sensor. A stopper is then inserted using a pick-and-place module featuring a burping tube to allow air escape during placement. Next, nasal actuators are introduced either via a secondary star wheel or in-line via pick and place. In either setup, the actuators are inspected to make sure cannulae are present and straight, then automatically placed around the vials, which are pressed into place with an automatic tamping device. Finally, the machine ejects finished unidose delivery systems into a collection bin. Options are available to further automate the star wheel system with automatic component placement.

The machine has an accuracy tolerance of +/-0.5% on a fill volume of 100 to 125 ml. Stopper position can be determined down to 0.3 mm. Additional inspection options are available, including a post-fill station that verifies fill volume, piston height, and unwanted fluid between piston ribs. Other optional stations can check for vial rim cracks following stopper tamping, as well as canula presence and straightness prior to actuator placement.

The unit’s product contact parts are composed of ceramic, stainless steel, and Teflon. It is controlled via a 7-in. touchscreen HMI with recipe control and the ability to turn on or off any station or inspection as required for the particular application.

“With intranasal administration devices among the fastest-growing forms of drug delivery, machine solutions that address all stages of their production are increasingly sought after,” says Deborah Smook, VP of marketing & business development for TurboFil Packaging Machines.