CSP Technologies, Inc.’s Activ-Seal™ closures feature orifice-reducing element is affixed onto the top of the bottle during the induction sealing process. It is covered by a lift and peel foil seal that once removed, enables metered dosing. The scavenging component, offering combinations of moisture, volatile organic compounds (VOC), and odor management, is permanently positioned on the underside of the orifice reducer, ensuring the product protection never leaves the bottle, even after opening.

Offering optimized capacity and uptake rates, Activ-Seal™ closures are designed to offer improvement over more traditional methods of ensuring product stability, such as inserting canisters or sachets, which require additional insertion equipment and carry the risk of accidental ingestion. Complexity and costs also are reduced, since only one molded piece is needed for all scavenging needs.

Key benefits of CSP Technologies, Inc.’s new Activ-Seal™ closure include the following:

• Metered dosing provides consumer convenience; orifice reducer opening can be tailored to various product sizes

• No canister or sachet moving freely in the product bottle

• Moisture and other gas scavenger materials cannot be removed

• Hazard markings “Do Not Eat” are not required; adsorption material is secured to the underside of the orifice reducer and is invisible to the consumer

• Technology fits within standard caps

• No additional packaging insertion equipment needed

• Integrated orifice reducer becomes part of the product container

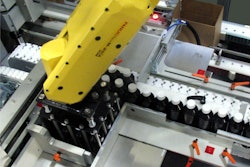

• Can be applied with standard capping and induction sealing systems

• Can release aroma for enhanced consumer experience