Amcor’s LiquiForm™ technology is targeted to bring energy and cost savings as well as other benefits to liquid packaging producers worldwide.

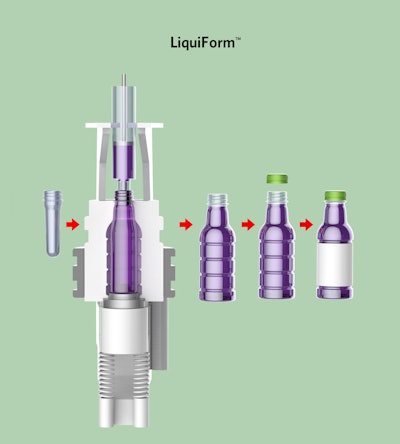

LiquiForm is a blow molding and filling manufacturing technology that uses consumable, pressurized liquid instead of compressed air to form plastic containers. By combining the bottle forming and filling processes into one step this technology eliminates numerous manufacturing steps, significantly reducing cost and waste.

LiquiForm technology benefits include the following:

• Energy reduction—no need for compressed air as the bottles are formed when they are filled with the beverage or product

• Improved sustainability—lower energy use means less greenhouse gas emissions

• Less cost to produce—no redundant equipment associated with traditional blow and fill operations

• Operational efficiency—reduced labor, waste, and downtime

• Reduced footprint—forming and filling are combined in one operation, reducing the amount of floor space required

• The preform is placed in the mold and then the liquid or product is forced at high pressure into the preform, molding it into the bottle shape. This results in a filled bottle, ready for capping and labeling.

LiquiForm technology has been validated with a significant range ofpackaging substrates, products, and conditions using the same LiquiForm machine for cold, ambient, and hot-fill containers.