The new FHM 1000 series from Bosch Packaging Technology offer semi-automated, modular laboratory devices for liquid pharmaceutical filling operations.

The new development is particularly suited for pharmacists and for the application in laboratories and early clinical trials. Its filling parameters can be scaled-up to production systems: all relevant parameters are measured and specified in the laboratory, and can then be transferred to production machines without further settings.

The development of the FHM 1000 prototype was based on early involvement of customers and end users in the process, offering customers compact and modular laboratory filling systems that support their everyday working processes.

The FHM series facilitates the design of experiments (DoE) for customers. Recording parameters makes it possible to precisely determine cause-effect relationships between influencing factors and target variables by involving customers' experience.

This “user experience” approach has been successfully implemented by the company in the electromobility sector. Bosch’s interdisciplinary team of development and market experts successfully implemented the user experience approach for the laboratory device FHM 1000.

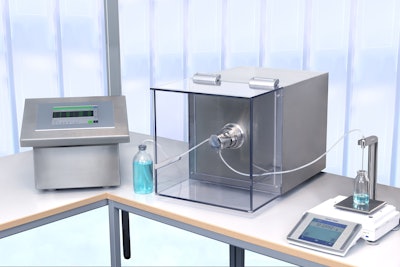

The laboratory device series currently consists of four different modules: the Human Machine Interface (HMI), the filling module, the weighing module, and the needle movement. All automatic processes are operated from the HMI, which serves as the centerpiece of the FHM 1000.

The filling process with its filling needle movement and in-process control (IPC) weighing are parameterized via the HMI, whereas in- and output of the packaging is done manually. The recorded results and parameters can be scaled-up and transferred to high-performance lines.

The prototype operates with a peristaltic pump. Further filling modules are planned, for instance, with a rotary slide piston pump. According to demand, the different filling systems can then be flexibly exchanged. The integration of a closing module is also planned, enabling packaging to be equipped with different types of stoppers. A protective housing for both the filling module and the needle movement ensure product and operator safety. All modules conform to the EU Machinery Directive 2006/42/EG.