A TLM packaging line demonstrated for the first time by Gerhard Schubert GmbH is flexible enough to produce batch sizes of one and has been configured to package tablet blisters for clinical studies for Hoffmann La Roche.

In the machine, products in two different dosages are prepared including personal labelling. The patient kits are put together in shipping boxes based on the study and labelled accordingly. All necessary data are provided and managed by a higher-level data control system (LMS). The Schubert Oacjagubg Nacgubes LMS system communicates with the MES system from Hoffmann La Roche.

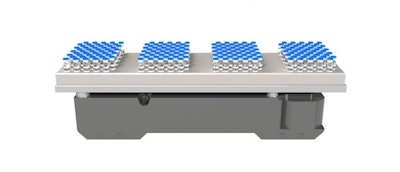

The machine handles blisters, vials, syringes, and is designed for future changes. The Hoffmann La Roche line has been equipped with transmodules (transport robots), which enables the flexibility for batch sizes of one. The photo here shows the transmodules carrying videos.

Also at the Schubert trade fair stand, a TLM picker line keeps 300 syringes/min in circulation in non-stop operation. Controlled by the Schubert Vision System, the syringes are taken from a continuously running infeed conveyor, placed on transmodules, and returned to the product infeed conveyor.

In the machine, products in two different dosages are prepared including personal labelling. The patient kits are put together in shipping boxes based on the study and labelled accordingly. All necessary data are provided and managed by a higher-level data control system (LMS). The Schubert Oacjagubg Nacgubes LMS system communicates with the MES system from Hoffmann La Roche.

The machine handles blisters, vials, syringes, and is designed for future changes. The Hoffmann La Roche line has been equipped with transmodules (transport robots), which enables the flexibility for batch sizes of one. The photo here shows the transmodules carrying videos.

Also at the Schubert trade fair stand, a TLM picker line keeps 300 syringes/min in circulation in non-stop operation. Controlled by the Schubert Vision System, the syringes are taken from a continuously running infeed conveyor, placed on transmodules, and returned to the product infeed conveyor.