Amcor has worked closely with some customers to further improve the accuracy of their vision systems by tinting the color of the product contact side of the package and improving visibility of the product for vision inspection systems through the development of Amcor Tinted Formpack®.

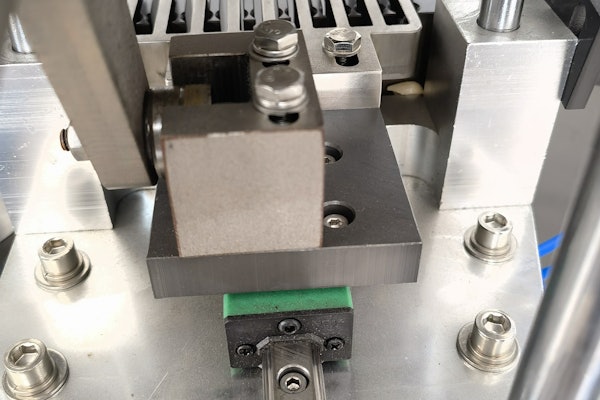

It's a cold-form material whose product-contact side is tinted with a color that contrasts sharply with the color of the tablet or capsule, thus helping automated machine vision systems differentiate between tablet or capsule and the background material in which the tablet or capsule sits. This helps eliminate false rejections and increases blister packaging line efficiency. The interior or tinted surface of Tinted Formpack has no impact on the immediate product-contact surface, so users of the material may be able to avoid additional stability testing. And that makes for faster product launches and speed to market. Those benefits helped Amcor earn an FPA Gold award for Technical Innovation.

Joe Wittemer, Amcor's product development manager, says the packaging material was first available commercially in late 2010 and is offered for any application utilizing a horizontal form/fill/seal process. He explains that the company does not have permission to disclose customer information related to this application.

Information provided by the FPA indicates that the product allows companies to package the full range of tablet colors without downtime and scrap caused by false rejections. Asked to elaborate, Wittemer says: “Many tablet detection units have difficulty detecting certain color tablets filled in blister materials. If the tablet is not detected, the blister card is rejected. Numerous rejections can cause the blister packaging line to stop. This creates both downtime and scrap. Tinted material eliminates this by creating a better background against which the tablet detection system can register the fill.”

FPA literature adds, “Blister packaging line efficiency is improved and overall costs are reduced.”

The OPA/foil/PVC barrier structure, Wittemer notes, “is only limited by the quality of seals in package. Due to the pinhole-free condition of foil-based laminate, product is essentially impervious to migration of moisture or oxygen.” The structure can be custom-printed or tinted. Amcor converts the material and ships it as rollstock to customers.

It's a cold-form material whose product-contact side is tinted with a color that contrasts sharply with the color of the tablet or capsule, thus helping automated machine vision systems differentiate between tablet or capsule and the background material in which the tablet or capsule sits. This helps eliminate false rejections and increases blister packaging line efficiency. The interior or tinted surface of Tinted Formpack has no impact on the immediate product-contact surface, so users of the material may be able to avoid additional stability testing. And that makes for faster product launches and speed to market. Those benefits helped Amcor earn an FPA Gold award for Technical Innovation.

Joe Wittemer, Amcor's product development manager, says the packaging material was first available commercially in late 2010 and is offered for any application utilizing a horizontal form/fill/seal process. He explains that the company does not have permission to disclose customer information related to this application.

Information provided by the FPA indicates that the product allows companies to package the full range of tablet colors without downtime and scrap caused by false rejections. Asked to elaborate, Wittemer says: “Many tablet detection units have difficulty detecting certain color tablets filled in blister materials. If the tablet is not detected, the blister card is rejected. Numerous rejections can cause the blister packaging line to stop. This creates both downtime and scrap. Tinted material eliminates this by creating a better background against which the tablet detection system can register the fill.”

FPA literature adds, “Blister packaging line efficiency is improved and overall costs are reduced.”

The OPA/foil/PVC barrier structure, Wittemer notes, “is only limited by the quality of seals in package. Due to the pinhole-free condition of foil-based laminate, product is essentially impervious to migration of moisture or oxygen.” The structure can be custom-printed or tinted. Amcor converts the material and ships it as rollstock to customers.