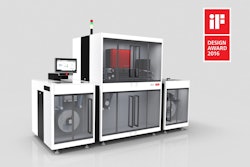

Videojet’s new Corner Wrap applicator for its 9550 Print & Apply Labeling system provides substantial improvements in production throughput for applications that require labeling on two sides of the case so it can be seen from multiple orientations.

The 9550 system prints the information on one continuous label and in a single process applies it to the two adjacent panels of a case, replacing two conventional applicators while ensuring that the information on both sides of the package is synched.

The new applicator also follows in the path of previous 9550 series applicators by eliminating most of the causes of failures, adjustments and maintenance in conventional applicators.

The conventional approach to two-sided labeling uses two labelers to apply two different labels with duplicate information. These label printer applicator (LPA) machines use either blow applicators or telescopic tamp applicators to apply printed labels to packs. Both of these methods rely on the accurate and timely placement of the label from the print engine onto an applicator pad.

When this mechanical process fails, the result is missing or wrinkled labels and sometimes damage to equipment. For example, a mistimed tamp applicator stroke can result in a collision with an advancing pack and can damage the applicator.

Conversely, the 9550 Corner Wrap system uses Videojet-patented Direct Apply™ labeling technology to affix the side section of a label.Next, a single pneumatic stroke of a wipe roller wraps the label onto the back of the case.

This simple design eliminates the swing arm that is typically used for corner wrap labeling and can often be a point of failure. Additionally, the 9550 method reduces wear and tear, as its applicator rolls across the back of the case as opposed to the front of the case where the case can directly impact the applicator arm.

Manual adjustments are frequently required in conventional LPA systems, and when these sensitive adjustments are not made correctly, the result can include label, web and ribbon jams and mechanical failures, all of which can result in downtime that brings the line to a halt, reducing production throughput.

The Videojet 9550 Corner Wrap system overcomes these problems by using Videojet-patented Intelligent Motion™ technology to maintain the correct amount of tension in the media supply reel from the first label to the last.

This design eliminates the need for manual adjustments and numerous moving parts, which have a tendency to fail and require maintenance, while at the same time helping to eliminate jams. The result is a reduction in downtime, which helps increase production throughput.

The trend toward increasing retailer and regulatory requirements, as well as increasing SKU complexity, is a concern for manufacturers seeking to safeguard their operations from costly labeling errors.In order to help manufacturers improve quality and adhere to applicable standards, the 9550 Corner Wrap system comes equipped with the Videojet industry-leading CLARiTY®touchscreen interface, which includes intuitive job selection, comprehensive feedback and diagnostics to minimize human error.

A single, integrated user interface removes the difficulties associated with dual interfaces common on systems based on Original Equipment Manufacturer (OEM) print engines. As few as three user touches are needed to select a job from an on-board job database. A step-by-step guided entry allows correct fields to be edited and bar codes to be created automatically by linking data from multiple text fields.Additionally, a preview of the job selection and the final message is available for additional confidence that the correct job is programmed.