FOX IV Technologies’ Tandem Label Printer Applicator enables the full use of tamper-evidence, serialization, and authentication—the three hallmarks of anti-counterfeiting technology—in one automated labeling system.

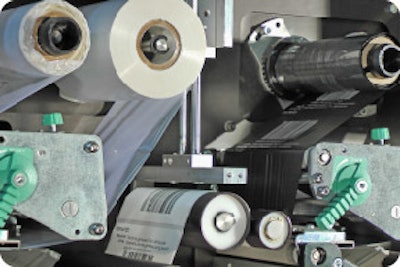

The FOX IV Tandem utilizes two in-line thermal print engines to print and apply customized anti-counterfeiting labels. Starting with unprinted or preprinted label stock, the Tandem’s first print station is able to print standard product and lot information such as the GTIN, serial number, lot code, and expiration date both in human-readable and liner or 2D bar-code format. The second print station, utilizing specialized ribbons, enables authentication measures to be employed.

Overt, covert, and forensic authentication marks can be printed in addition to the information printed at the first station. Overt anti-counterfeiting printing may include a holographic printed image, a specialized color, or a scratch-off patch printed over top of lot-specific information. For more covert anti-counterfeiting measures, the second print station may apply text or bar code information printed in UV ink, which will only be visible under black lights. Forensic tracers or specialized covert markers can also be applied to the label at the second print station. To ensure the label is not tampered with once it has been applied, tamper-evident label stock can be utilized.

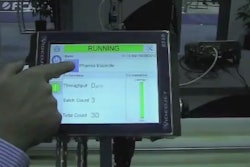

The FOX IV Tandem automates the entire anti-counterfeiting labeling process by printing and automatically applying the unique label to the product, case, or pallet. The dual in-line print stations are designed to accurately print the two-process label without label web tracking issues and the large 16-in. OD label roll capacity ensures extended production. Various label application methods are available depending on the item being labeled. A high level of label placement accuracy can be achieved. The Tandem easily integrates into existing production lines as an integral part of the product identification, verification, and tracing process.