Manufacturers uncertain about implementing serialization to comply with the Drug Supply Chain Security Act (DSCSA)/Drug Quality Security Act (DQSA) may turn to their packaging suppliers for answers so they can focus on other issues such as R&D, product development and speed to market.

One of those companies people are turning to is Domino.

“While some companies have been leaders from the outset, the ever-changing California target dates resulted in many companies taking an investigational view of things without moving too far into the process,” says Mark Shaffer, Domino’s Life Sciences Business Development Manager. “With the transition from California e-pedigree to DQSA, the overarching change we’ve seen is that most companies have accepted that the deadlines are now firm and they need to proceed.”

With serialization, companies understand that they need to code differently, but many aren’t sure exactly what is required and how to accomplish the task.

“Successful printing of a serialized code involves a lot more than just a printer,” he explains. “We need to assess how the printer will be integrated, where the data will come from, and determine if the packaging materials are compatible with the chosen coding technology. If not, what changes are required?”

Domino doesn’t just partner with its customers, but also with multiple vendors to determine the most effective method to print machine-readable codes on a range of packaging materials.

As an example, Shaffer cites Domino partner 3C! Packaging.

“They were working with a customer to provide labels and cartons that are conducive to printing serialized codes using laser technology,” he says. “In addition, they didn’t want to compromise their brand image by adding a ‘black box’ (to allow the laser to ablate a code onto a white box). The customer also did not want to slow down the production line when adding the serialized code.”

To address that customer’s challenges, 3C! and Domino used a pigmented coating from Datalase called Clear Code. Not only were they able to eliminate the need for a black box, but the customer was able to increase production speeds by 10 to 15 percent, Shaffer notes.

“We’ve learned to take a holistic view of serialization for software, coding equipment, vision inspection, packaging equipment (labelers, cartoners, etc.), and packaging materials,” he says. “These are all interconnected and dependent upon each other. The failure of one component can mean failure of all components.”

Recommendations for manufacturers

For manufacturers, Shaffer says, “it’s important (that customers) build a team of subject-matter experts, both internally and externally. Internally, many departments will be impacted and should be stakeholders in the process and involved from the earliest planning stages. Externally, it’s vital to choose vendor partners that are not only experts in their own arena, but should have a thorough understanding of what a successful strategy looks like.”

He believes that by following these steps, pharmaceutical companies will “help mitigate the negative impact to Overall Equipment Effectiveness that is universally expected (at least at the start) when implementing serialization.”

Customer input

Sanjay Patel, Vice President, Global Supply Chain at Akorn Pharmaceutical, identified three steps it took to launch its serialization program:

• Educating stakeholders and executive management of the regulatory requirements and project complexity

• Setting up a cross-functional team

• Idenfifying various potential partners to guide in early project stages

Akorn saw prioritizing the serialization project as a key company initiative while managing ongoing business needs as the company’s largest challenge in the process. The pharmaceutical company sought Domino’s expertise in providing an initial assessment of the implementation requirements, identifying potential vision system providers, and deciding the best approach for identification placement.

A key factor for manufacturers is to find a vendor that has the resources to meet future demand.

“When considering a supplier of coding equipment for serialization, companies need to consider partners that can provide expert guidance on their packaging structure and design to ensure optimal code quality,” says David Mason, Global Program Lead, Sandoz. “They should confirm that test lab facilities exist to evaluate not only print quality, but also the packaging substrate to be printed. It is also important to select partners that have existing relationships with other OEM partners to leverage their knowledge and experience. If you are a multinational company, partners with global service and support are vital.”

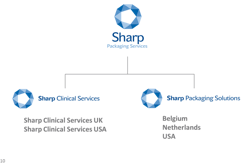

Rick Seibert, VP Project Management and Technology Services, Sharp Packaging Services, says it’s important to “partner with the most technically competent and passionate companies in the market. In working with our partners, the better off we all are, the better our customers are will be served.”

Global serialization

Domino has been involved in pharmaceutical serialization since the 2004/2005 timeframe, both in the U.S. and around the globe. For example, the company works on projects including CIP 13 in France, Turkey, Korea, Saudi Arabia, and in the European Union.

Global scalability allows companies to better meet compliance issues in other regions.

“Almost every month there is a new country where we are deploying and we need to have local support from our partners,” says Louis Roy, President, Optel Vision. “Domino has that. They have a global reach and they are experiencing similar expansion. Working with common partners is beneficial for all parties involved, especially our customers.”

When it comes to controls, automation, and storage systems used in packaging lines and for serialization, Shaffer says Domino takes an agnostic standpoint.

“In order to ensure our customers’ success, we need to work with whatever partners they choose,” he says. “We work with virtually all key OEM’s and serialization providers to educate and support their activities and projects.”

Looking at the future

As his company looks ahead to serialization over the next three to five years, Shaffer explains, it’s not just in pharmaceuticals.

“There are legislative initiatives in medical devices, veterinary products, and other areas that exist concurrently,” he says. “And these are being driven in various countries around the globe. New initiatives will continue to be created. What we’re all learning from pharmaceutical serialization is helping to simplify the implementation process into these other segments. However, with legislation expanding quickly, the question remains, ‘Can the supplier base continue to keep up and expand nationally and internationally to support these initiatives?’”