AVT (Advanced Vision Technology), in alliance with Erhardt + Leimer (E+L), premiers a broad array of inspection and print process control systems.

The company’s Helios S Turbo is an inspection system designed to help production lines reach maximum potential through increased printing and rewinding speeds. Helios S Turbo uses modern machine vision technology to help printers get more from their inspection systems. Incorporating the Turbo system into a line allows operators to rest assured that no print problem will be overlooked, regardless of inspection and production speeds.

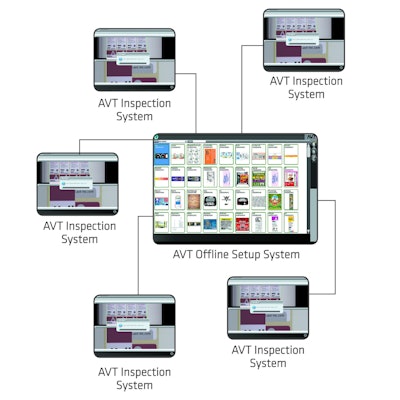

Offline Setup is an automation tool that helps customers create quality standardization across their production operations or maintain quality standards between different jobs and runs. By standardizing quality thresholds and addressing the needs for production processes automation, the system helps raise the bar for overall print quality. Offline Setup enables enhanced setup consistency and suitability between operators, where all settings are made by the same operator for all AVT inspection systems.

SolidProof is an offline proofing system that provides 100% assurance for wide web, narrow web, and sheet-fed applications, ensuring that no critical errors have been overlooked in the print production process. This automatically eliminates conversion errors and undetected defects during the prepress stage; in doing so, it drastically reduces the need for manual inspection and can bring waste levels to near zero. This product is part of the new AVT Offline proofing line that also includes SoftProof and CloudProof.

AVT also offers a print quality control engine for inkjet digital presses. It provides digital printers with a closed loop system for inkjet printing quality by analyzing its actual performance through the run and engaging in ongoing communication with the press.

AVT has also introduced a system that provides fully automated inspection and verification throughout the entire digital printing process. This combination product includes the ZeroSet Automated Inspection Workflow, which addresses market needs for inspection on shorter runs and better support for digital printing presses. ZeroSet makes possible universal inspection—meaning even very short runs can be automatically inspected—leading to a direct improvement in overall quality control for jobs that previously may have been left uninspected.