In the bottle industry there is always an application to solve no matter if it is bottle empties, label, filling level, or cap inspection.

EVT offers with the latest EyeVision software version, commands, which in this field of machine vision entail innovation.

EyeVision identifies damaged and empty non-brand bottles during the fully automated return of empty bottles. This can be carried out by recognizing the bottles by means of several characteristics such as height, diameter, color, or label of the bottles and is able to discharge damaged bottles or bottles of a different type.

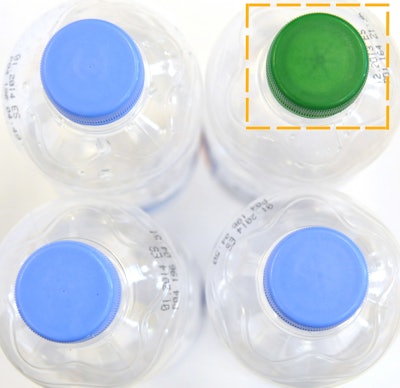

The cap inspection with EyeVision allows a high-precision measurement of an askew bottle cap. Eye Vision starts with the presence check of the bottle cap and the inspection of the lock ring up to the inspection of the cap height, and this at speed of 30 bottles/second.

The EyeVision software also proves of value in the bottling plant. For example, to check if the fill level is matched by every bottle, an image of the bottle neck is captured and the fill level is measured. Also, before the bottling, the bottle neck is checked for cracks or if its splintered.

EyeVision software also works during label inspection, even if the labels vary not only in content type and packaging, but also in language, origin, and size. The inspection is carried out in free run on the conveyor band, on any kind of bottle, totally impartial to the type and position of the label.

It is also possible to control various 3D sensors with the EyeVision software, making it possible to check the bottle cases with a 3D-system. Therefore it is possible to detect if the cases are accordingly filled with bottles. With top view it is not only possible to check if the cases are completely filled, but also if there are some other disturbances.

Due to the intuitive drag-and-drop programming, the EyeVision software is easy to handle and suitable for users without programming skills.