SP Thermoforming, the North American brand of UK-based Riverside Medical Packaging. Ltd., introduced a line of flexible and rigid blister thermoforming machines featuring a potentially game-changing concept: carousel design. A departure from linear, meters-long chain-pulled thermoformers, the SP Series performs all necessary functions via a rotating drum through its radial workstations.

The SP Series is suitable for pharmaceutical, medical device and food applications, and can form both rigid and flexible/soft blisters. In the U.S., Mexico and Puerto Rico, SP Thermoformers and local support are available through BTS International LLC, a packaging machinery sales and consulting firm.

The SP Series offers what is reported as a first-of-its-kind carousel design that reduces each machine’s overall footprint—an asset in stark contrast with traditional linear thermoformers. The design also reduces the amount of labor needed to operate the machines, allowing manufacturers to reallocate manpower elsewhere.

The new SP Series’ thermoformers are approximately 30% less expensive on average, significant considering that prices for blister machines can reach the high six figures.

Operating costs for the SP Series are kept at a minimum, with factors including single-phase low energy consumption and easy repositioning. No water cooling is necessary. Simple tooling design helps lead to quick changeover, while simplified loading geometry allows for efficient and cost-effective automation.

Other important SP Series benefits include the elimination of gripper chains and trim, resulting in reduced maintenance, contamination and downtime. In addition, products packaged via the SP Series are placed directly into the actual mold that creates the form and remain until the packaging process is complete, eliminating product edges getting trapped in the seal.

The SP Thermoformer portfolio comprises eight machines, the largest of which can handle web widths up to 620mm, indexes up to 250mm, and forming depths up to 100mm. The entire series is capable of handling variable web widths on a single machine. Dozens are currently in operation around the world, many with repeat customers.

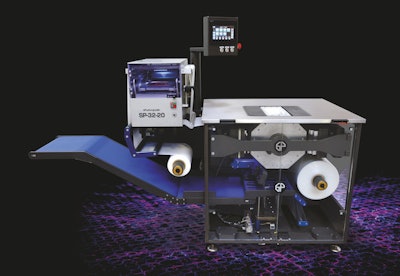

Among the most popular in the new line of thermoformers is the SP-32/20, which handles web widths of up to 320mm, indexes up to 200mm, and forming depths up to 80mm. The machine can produce up to 34 cycles/min. Its standard features include airflex form and seal bellows with pressure control, stepper motors for indexed drive, lockable form and seal heads, cross cut, and positive discharge mechanism.

Various automatic and digital options further increase the machine’s efficiency and, at approximately one cubic meter in size, the SP-32/20 capabilities-to-footprint ratio is said to be unparalleled.