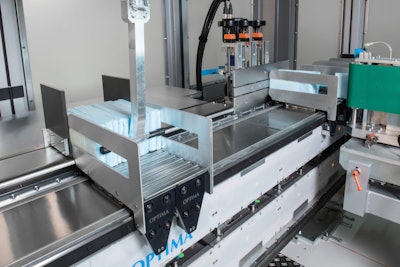

Optima Packaging Group’s new LS Stacker processes up to 1,600 units/min, and forwards them in stacks of up to 100 units to downstream packaging machines. LS Stacker can handle bundled bed liners, incontinence products, and other nonwoven stacks at a maximum of 5 kg per bundled stack. Increased flexibility is an additional advantage of the new system.

Due to the high speeds, considerable g-forces are exerted on the product mover and the guides of the Optima LS Stacker. These forces are compensated by way of the inherent magnetic fields of the linear drives. The magnetic forces that are generated allow for secure guiding of the products across the entire movement. With the use of this newly developed system, the advantages of the linear drives can be fully exploited.

Maximum output to date is 800 units/min, and 75 product stacks/min. With the new drives and output, the stacker enters the domain of diaper packaging speeds and can therefore be used for this application as well.

Newly designed cassettes on the LS Stacker take up the products. Instead of base plates, the new cassettes use intermeshing forks. These can be adjusted as needed to suit the pitch of the freely adjustable mover. Format changes can therefore be made “on the fly” at the push of a button. Only when the maximum or minimum pitch of the forks is reached is a manual intervention and replacement necessary. With this system, product and customer-specific forks can be designed to accommodate the largest number of products or stacks within a customers’ portfolio, minimizing the need for manual changes. Customization for “low counts” or small packages is also possible.

Another feature of the new LS design is the tightening function. The product stack, which is in the cassette, is held and calibrated for a specific force. This function generates several advantages. First, a stable process is guaranteed since the products in the stack are held tight. At the outlet of the machine, the stack is tight and secure, which is important for secure product handling processes at high speeds. The tightening also has a secondary effect: Additional tightening or compression of the stack is no longer required in downstream machines.

The new mover cassettes are compatible with existing packaging processes; the typical “standard” transfer is unaffected. Despite this new variant of the LS Stacker, the original variant with the lower output is still being offered. The footprint of both variants is nearly identical. The new Optima LS Stacker can be intelligently combined with various packaging machines supplied by Optima nonwovens.