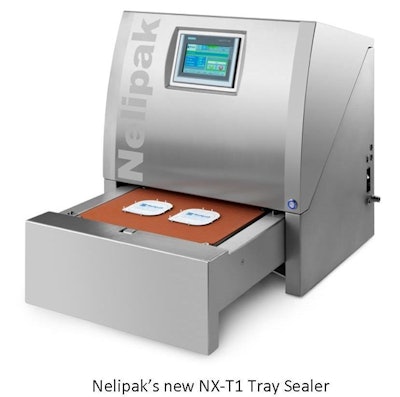

Nelipak’s next-generation machine, the NX-T1 tabletop heat sealer, requires little maintenance and is Class 7 and 8 Cleanroom-compatible. Fashioned in stainless steel for ease of cleaning, the machine incorporates several new features, including an automated sealing drawer. Touch-button control activates the hands-free sealing drawer that automatically closes to begin sealing cycle and returns to open position on completion. In the open position, automatic pushers release trays for ease of removal from the die, reducing wear on the critical seal flange area.

The automated cycle frees the operator to prepare the next tray in the sealing process. The sealing drawer features the Nelipak quick tool-change system for sealing dies and heat plates, reducing setup time of production parts. The drawer automatically defaults to the open position, which prevents the sealing die from overheating if inadvertently left under the heat plate when not in use.

The NX-T1 features an upgraded Siemens PLC HDMI Controller allowing for additional functionality to be built into the system. This facilitates the new RFID built-in reader, which confirms correct tool set. Recipes are selected by the operator, and the system locks out if the wrong tool/recipe combination is selected.

Software upgrades enable 21 CFR 11−compliant logging of inputs providing audit trail data and include logging of pressure, time, and temperature parameters. Additionally, logging of seal force (load cells) pressure during the sealing cycle is available as a machine option.

Access control to the machine and its functions can be programmed according to the operator levels required. Accessibility to both the machine and interface are among many of the new features Nelipak incorporated into this new model. Built in stainless steel, the casing is compatible with Class 7 and 8 Cleanroom manufacturing and results in lower cleaning requirements.

The NX-T1 is fitted with a new compact air cylinder with the same pressure force as Nelipak’s SH-BT1 model and features a new frame connection equipped with load cells to measure sealing force. The NX-T1 sealer is built with the operator in mind; its ergonomic design reduces physical strain with all controls—power, airline, and

communication plug-ins—in easy-to-reach locations. The NX-T1 comes with RJ45 socket connection for network communication and 2x USB connection ports for printer or other peripheral USB equipment. A new hood opening feature allows ease-of-service access from the front of the unit. Pneumatic and electric components inside the machine are separated for ease of servicing. Full 360° access is possible with the hood removed for maintenance and validation work.