“Better safe than sorry” can refer to any number of subjects. But for a large biotechnology firm’s Netherlands-based facility, that phrase takes on critical importance in packing vials and pens in 13 different configurations.

In order to expand its capacities and modernize its packaging line, the biotech firm’s project managers and engineers wanted to automate this small-component packaging task to help increase efficiency and save production costs. Any packaging solution needed to provide flexibility and precise handling for the biotech firm, which preferred not to be identified.

From its locations in America and Europe, the biotechnology company provides patients with medicines for cancer therapy or severe chronic diseases and metabolic disorders. To ensure simplicity, safety and overall patient compliance, the manufacturer produces vials and pens for precise dose administration of a drug to battle high cholesterol. The products require special handling care during the packaging process to prevent glass breakage and to avoid activating the pens prematurely.

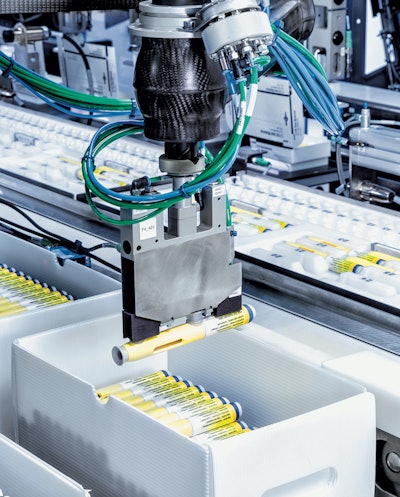

The company selected TLM-machines from Schubert, equipped with the transport robot Transmodul and a novel 3D camera.

Until this application, the company had not deployed any Schubert equipment worldwide. During a face-to-face meeting, Karin Kleinbach, Sales Account Manager at Schubert-Pharma, contacted the pharmaceutical company, which was convinced that the Schubert TLM modular platform would help it meet its needs at the Netherlands facility. To meet these challenges, Schubert-Pharma developed a combination of robot technology and advanced 3D image recognition.

Designed for safety

In the design of the machine, gentle product handling was given top priority, with special attention paid to avoiding glass-to-glass contact. To meet this requirement, the vials and pens are placed into fluted paperboard dividers or preformed trays within the cartons.

Only extremely low forces could be exerted upon the products during this process. 60N force was the limit set by the biotech firm to ensure that the sensitive products would not be damaged and that unnecessary production downtime would not occur. Should this value be exceeded, the machine stops to enable checking of the problem source and removal of the products from the working area.

Examining the packaging process

Packaging begins with the feeding of the standing vials on a conveyor belt that transports them to the F4 robots. A camera detects their position on the belt and simultaneously controls the presence of the caps. An F4 robot then grips one vial from the belt and groups it horizontally on the Transmodul. Meanwhile, the pens get fed to the F4 robots in transport crates with 120 pens each on a separate conveyor belt.

In the carton erecting station, the blanks for the vials or the pens are denested from a magazine and erected. During this process, the pharmacode on the blanks is controlled and verified. Blanks with incorrect codes are rejected beforehand so they do not enter the packaging process.

The erected cartons are placed on a Transmodul and forwarded to the next processing phase, where they are loaded with trays or partitions. Just like in the first packaging phase, the blanks are fed into the machine via a magazine.

A combination consisting of F2 and F3 robots folds the partitions before they are placed into the product cartons. Sensors on the robot tool ensure that each carton has been provided with a partition or tray respectively.

Then the pre-grouped products – pens or vials – are placed into the cartons. In order to ensure safe shipping, the vials and pens are securely snapped into the trays or partitions of the cartons.

Precise handling through spatial control

During the packaging process of the pens, a new 3D camera from Schubert, developed specifically for this project, is applied. Transport boxes with 120 pens are placed on a table in front of the picking robots. The F4 robot takes the pens directly from the transport boxes and places them in pre-grouped formations. After each product is taken, the 3D camera scans the contents of the boxes and determines the exact position and layer height of each individual pen.

Data from the process are passed on to the F4 pick-and-place robot, ensuring that each product, even if its position has changed following removal of a pen, can be precisely targeted at the next product intake. Empty shippers are automatically discharged from the machine.

In the next module, F2 robots pick the product leaflets from a magazine and place them in the product cartons. Prior to inserting the leaflets, the pharmacode on the leaflets is controlled and verified. Leaflets with incorrect codes are rejected before entering the packaging process.

In the final step, cartons are closed. Cartons not completely filled or firmly closed are detected and ejected. A conveyor belt moves the controlled products to downstream processes.

The biotech company was pleased with the technical concepts of the system as well as the scalability and resulting flexibility of the TLM line.