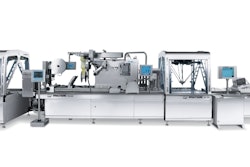

Bosch Packaging Technology has introduced a vial inspection machine to the AIM 8 series. This machine is the first of the

new generation of fully automated inspection machines offered by the Inspection Technology sector of Bosch Packaging Technology. In the future, additional models will be added to the series to cover parenteral liquid container types, such as syringes, cartridges, and ampules.

The AIM 8 series is characterized by a modular design for easy adaptation to customer-specific requirements. For instance, customers can choose from standardized inspection units or add an extra inspection table. The basic module of the AIM 8 is equipped with a CMOS camera-based particle inspection system and a table for up to five inspection stations. Each station can, in turn, be equipped with a wide range of different inspection units. Most of these units combine two inspection types, leading to space savings on the tables. Depending on their requirements, customers can expand this main module by connecting it to a sub-module containing an additional inspection table, as well as to a pre-spin table to reduce bubbles in liquid or homogenized suspensions. In contrast to previous series, a camera system is integrated into the main module as a standard particle inspection unit.

The new AIM 8 series is designed to inspect up to 600 cpm for product and cosmetic defects, such as particles inside liquid pharmaceuticals or scratches and spots on the container. Depending on product requirements and customer preferences, the light transmission−based SD (Static Division) system for the inspection of moving objects and fill levels is optional. The puck transport system ensures quick and easy size changeover and safe container handling.

Bosch has also introduced the fully automated ETIM tablet inspection machine. Developed exclusively for the Japanese market, the machine is now making its first appearance outside of Japan.

The ETIM is designed to flexibly handle different types and shapes of tablets at output rates of up to 300,000/hr. The inspection machine identifies tablet defects such as coloration, breakage, and foreign particles as small as 50 µm in size. The camera-based imaging system ensures a 360-deg inspection of each tablet. It simultaneously inspects the tablet surface and its peripheral edge with a single camera, presenting the information as five images on the operating screens. The opposite side is inspected with the help of a precise tablet flip-over during transport. This leads to all-around inspection by avoiding blind spots or dead angles.