As time-to-market cycles in the pharmaceutical industry grow shorter and shorter, the machine concepts need to offer more flexibility. Aseptic filling and closing systems company groninger’s FlexPro 50 is for small batch production and represents a turnkey partnership with Martin Christ Freeze Drying Systems.

Like many other sectors, the pharmaceutical industry also experiences a trend towards greater specialization in medicines, which results in smaller batch sizes of mostly cost-intensive biotech products. Smaller batch sizes often demand high flexibility due to processing different containers and products on the same filling line.

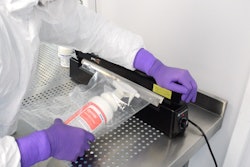

Ensuring sterility in these circumstances without compromising productivity calls for a flexible filling system that can be easily re-equipped for the most important standard containers. Increasingly, pre-sterilized objects are used for aseptic filling and closing of cost-intensive biotech products, where the trend moves towards smaller batches. With this in mind, groninger developed the FlexPro 50 Ready-Engineered machine concept to process pre-sterilized, nested and ready-to-use syringes, cartridges and vials.

By changing few size parts, nested syringes, cartridges and vials can be filled and closed with FlexPro 50 in one line configuration. Interchangeable machine trolleys permit additional line configurations allowing for an integrated nest/bulk process line which achieves an output of up to 4,700 objects/hr.

FlexPro 50 allows for various manual or automatic processes to cover market and customer requirements. Aside from standardized coordinated line modules in a highly compact design, a major advantage for operators is the access to the machine modules at both sides. This enables a full technical integration of the isolator modules and particle monitoring system. The concept is designed to save up to 40% of space compared to conventional systems.

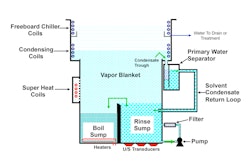

Full integration of the air supply in the isolator allows for air exchange with the ambient air - so no additional space is required in a machine room. The decontamination cycle has been reduced by 50% compared to conventional isolators thanks to a newly developed direct injection system.