The main purpose of containment systems is to avoid product release, thus assuring operators and environment protection from the exposure to potentially toxic substances. Isolators can also be utilized to protect the product from both external contamination and environmental unsuitable conditions, by keeping constant parameters such as the temperature and relative humidity level.

For operator safety, some OEL (Occupational Exposure Limit) thresholds have been defined, establishing the maximum product concentration level/cubic meter under which an operator being exposed for 8 hours/day does not run any risk. Based on the product to be handled the customer defines the best OEL level. Such limits are typically managed by means of a classification into OEB (Occupational Exposure Band) classes, which determine the admissibility range. For example, OEB 5 class covers the range between 0,1 µg and 1 µg of product/cubic meter. The higher classes (OEB4 and OEB5) are required for strongly active and/or toxic pharmaceutical products, such as those utilized for cancer treatment.

MG2 machines can be equipped with different systems suitable for all OEB classes, based on the containment strategy required by the product. Using isolators equipped with inflatable gaskets, gloves and an RTP (Rapid Transfer Port) is of primary importance to satisfy the higher class requirements (OEB5/OEB4).

Innovative pharmaceutical production trends

MG2 is investing in the study and development of such heterogeneous systems based on both the increasing number of projects which foresee the adoption of containment strategies, and systems to comply with more restrictive criteria in terms of control and safety followed by the pharmaceutical companies.

The adoption of containment strategies is a practice that’s been utilized for long time to handle highly active products. In recent years, many companies put into force in-house regulations foreseeing the compliance to high containment classes even when less critical products are to be handled with new production lines. This willingness is going hand in hand with another important trend giving priority to the adoption of containment system on the machine instead of the utilization of personal protective equipment for the operator (PPE – Personal Protective Equipment), which are usually expensive and not ergonomic as they hinder free movements. This choice also makes it possible to take advantage in terms of production environment conditioning by allowing users to keep high air quality in smaller areas than it would happen by utilizing machines being not equipped with containment systems.

Isolators, filters and cleaning systems to achieve OEB4 and OEB5 classes

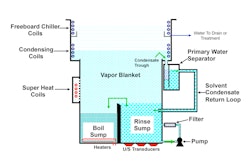

MG2 isolators guarantee the highest containment level (OEB5/OEB4) for machines being specially dedicated to the production of either a specific product or generally high toxicity powder products, independently from their production capacity (low/medium/high). The isolators integrate to both automatic product loading systems and high containment valves.

One of the innovations introduced by MG2 in the isolators field consists in directly fixing the suction filters to the isolator. In the past, filters were placed near the suction system at a given distance from the machine. This required the adoption of special systems to correctly wash the air ducts. The new location makes it possible to immediately filter toxic/active components, which do not contaminate the ducts, allowing easier cleaning and maintenance operations.

Filters utilized by MG2 adopt the “push-push” technology, which makes it possible to perform the replacement under more practical and safe conditions. The cleaned filter is simply pushed into its correct position from the external of the isolator by causing the ejection of the dirty filter inside the isolator, where it will be taken out by means of the gloves and through the RTP port.

To further satisfy the customers’ requests in terms of operator safety, MG2 rigid isolators include three possible solutions that can be upgraded as far as the combination of containment and washing functions. The first option involves the isolator carrying out containment by means of suction hoses to execute dry cleaning. The second possibility adds a spraying system to let the product lie at the end of production (Wet-in-Place). The third method provides the maximum automation level with a Wash-in-Place/Clean-in-Place automatic system followed by drying. In the scope of each solution the final customer can chose among a series of devices and optional functions covering the needs of each special application.

Intermediate containment levels

Thanks to both the wide scalability and the flexibility of its products range, MG2 can satisfy also the requests for intermediate containment levels by proposing easier and cheaper solutions if compared to the actual rigid isolator.

Already in their standard configuration MG2 machines deliver important isolation features. The Planeta capsule filler, during normal operation, complies with OEB3 class limits via its suction/vacuum systems that create a constant negative pressure inside the dosing area.

By upgrading the machines with typical additional containment parts, it is possible to reach the OEB4 level, which is sufficient to comply with many applications. The capacity of the protection hood can be increased by adopting the so-called “Enhanced Hood,” which, upon request, can be equipped with: gloves to carry out either adjustment operations or maintenance, nozzles to suck the product at the end of cycle (dry cleaning) or spray guns to perform moisten operations by spray (wet cleaning). To carry out all these operations would normally be necessary to open the doors, but with the above containment accessories they can be performed in a close environment, which is a controlled environment. The Enhanced Hood is also equipped with a filter placed on the air inlet duct, which further separates the product handling/dosing area from the production room.

Certified quality

During the steps that follow machine production, particular consideration is given to the performance of some tests necessary to both verify the capacity level and certify the OEB class to be assigned to the machine. These tests can be run at MG2 before delivery, or at a customer site once the machine installation has been done. MG2 follows the SMEPAC procedure (Standardized Measurement of Equipment Particulate Containment). The performance of such tests is assigned by MG2 to third-party companies that specialize in carrying out trials and issuing the relevant certifications to guarantee strictness, objectivity and compliance.

Recently, the SMEPAC test was performed on a FlexaLAB capsule filler equipped with containment for a multinational company, giving better results than the lower limit of OEB5 class. The same result was achieved for a TEKNA capsule filler with containment produced for a customer in Portugal involved in the development and in the production of inhalation pharmaceutical products. Also, a PLANETA 200, MG2’s core model for capsule fillers, esd sold both in a configuration allowing itto reach the maximum containment level, and in a configuration with the Enhanced Hood.

The preparation of the machines, the development of systems and the performance of SMEPAC tests are facilitated by the adoption of the Pharma Zone, located at MG2 headquarters. Here, it is possible to run dosing tests by utilizing active products under real production conditions before machine installation, resulting in savings of both costs and time during commissioning.