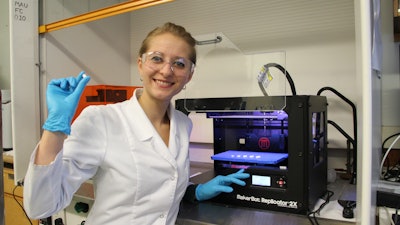

Britain’s University of Central Lancashire (UCLan) is developing a 3D printer that can produce a tablet containing a precise quantity of medicine, with the potential of creating customized drugs for individuals. The device uses a new drug-polymer filament system to replicate complex tablet design. Researchers predict that hospitals and drug makers will use the technique within the next five years and hope that eventually patients who require daily dosage changes could use the printer in their homes.

The UCLan team says that the machine, which is awaiting a patent application, can “print” a tablet with a precise quantity of medicine that can be taken by a patient.

Although the printer can reproduce existing drugs available in drugstores and hospitals, the UCLan team says that the main advantage of the printer is that it could potentially tailor drugs to a patient’s needs.

The new technology was made possible by a drug-polymer filament system that can replace the original filaments in a 3D printer. This new system allows the printer to replicate a complex tablet design, matching dose and weight with a high level of accuracy.

The system can provide medical institutions with a new option and maintain dosage form properties while accurately adjusting the dose with simple software order—something that was previously considered costly and required experienced staff and dedicated facilities.

Dr. Mohamed Albed Alhnan from the School of Pharmacy and Biomedical Sciences says, “3D printing has been embraced by lots of different industries, but we have shown how this technology can be harnessed to improve medical care, providing low-cost, personally tailored medicines for patients. Thanks to this technology, the invented system can provide medical institutions with a new option and maintain dosage form properties while accurately adjusting the dose with simple software order, something that was considered before to be costly and required experienced staff and dedicated facilities. Eventually, we hope to see that units can be kept at home for patients who continuously need to change their daily dose.”

When asked specifically about applications in packaging, Alhnan suggested that for 3D printing to be justifiable, “a significant need for continuously changing of packaging design, capacity, and properties will have to be established.”