This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Moeco, a provider of visibility solutions that improve global supply chain operations, has developed a new generation of disposable cargo trackers that enables logistics companies to significantly reduce costs through improved visibility into the location and condition of every package and shipment.

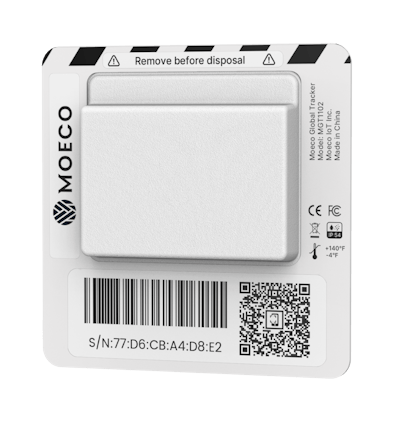

The Moeco Act tracker uses 4G and 5G cellular networks, and supports 2G and 3G network data gathering to provide logistics companies with real-time access to geolocation, temperature, humidity, light, and shock data. The tracker complies with International Air Transport Association (IATA) standards—ensuring safe, sustainable, and efficient operations while supporting harmonization across the aviation industry.

Real-time tracking means that cargo acceptance at intermediate points of the supply chain is automated, and the number of goods that need to be checked manually is reduced significantly. Since conditions are continuously monitored, only those goods that have violated the conditions of transportation require manual checks by staff, reducing checkpoint labor costs.

Logistics companies can access analytics on shipments in real time through a cloud platform via dashboards and one-time trackers that are easily affixed to packages and boxes. This enables logistics companies to offer premium shipment tracking and disposition services to their customers.

The Moeco Act tracker contains less than 2 g of lithium, which means it can be disposed of as plastic waste.

Alexa Sinyachova, CEO and co-founder at Moeco says, “There is a pervasive misunderstanding in this industry that any reusable item is better than a disposable item, when in fact, a reusable tracker has a higher CO2 impact than a disposable tracker. This is because only 5% of all shipments require two-way tracking—or reverse logistic—but reusable trackers must be returned to the original location once a shipment has reached its destination. In addition, manufacturing a reusable tracker generates more CO2 than the production of a disposable tracker, since the battery in the reusable tracker is larger.

“Most importantly, a disposable tracker does not require reverse logistics. Upon arrival at the end point, it is folded in half, so that electronic components can be disposed of as e-waste, with the rest as recyclable plastic. We advocate the use of disposable trackers—it’s far better for the environment at a time when there is a need to focus on sustainable supply chains.”