Hoffmann Neopac, a manufacturer of barrier tubes for pharmaceuticals, cosmetics, and oral care products, has entered into a partnership with Saperatec. According to the agreement, Hoffmann Neopac will supply its production waste to Saperatec, which is building the first industrial recycling plant for aluminum laminate composites, following its opening in mid-2023. Aluminum barrier laminate tubes are usually downcycled or incinerated and, depending on the country, packaging may end up in landfills.

Tube products with aluminum barriers continue to be necessary, since they meet the most stringent requirements for barrier properties, especially for pharmaceutical ointments and creams that must go through a regulatory approval process. These tubes represent approximately 10% of the laminate tubes manufactured in Europe.

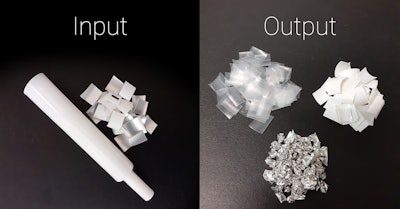

In a pilot plant, Saperatec demonstrated its ability to break down multilayer composite materials, enabling a high level of material recycling. Utilizing a special washing technique, Saperatec has proven it can separate plastic and aluminum layers without dissolving them. For instance, a spring 2021 laboratory study at Saperatec with a variety of Neopac ABL tubes demonstrated that Polyfoil® tubes, for example, can be completely separated in this fashion.

Following the separation process, the materials are sorted, producing fractions of polyethylene and aluminum, which can be recycled. Scheduled to start operations in mid-2023, the Saperatec Dessau, Germany, industrial separation facility will be capable of recycling composite packaging waste made of aluminum, plastic, and paper.

Initially, Neopac plans to feed production waste generated at Saperatec in larger quantities to the special separation process. Then, Neopac and Saperatec will examine the technical possibilities for applying recycled, materially separated production waste to the production of new tubes.