The product fraud and counterfeiting threat is complex and extremely interdisciplinary. This is one reason it is such a growing threat and why the FBI calls it “the crime of the 21st century.” The challenge of selecting effective countermeasures is that criminals can be very adaptive and have a huge financial incentive to develop ways around security systems.

While there may be a slew of new or pending regulations, corporate leaders are realizing they need to tackle the threat from counterfeiters for simple business reasons. Counterfeit product and product-related fraud is creating current vulnerabilities that expose the business to tremendous risk of lost sales, recalls, or legal liability. These vulnerabilities are amplified by the global economic recession where protective countermeasures may have been reduced at the same time that counterfeiters have become more aggressive.

There is a need and a trend for corporations to take a more holistic and strategic approach. While packaging managers are often assigned to implement an anti-counterfeit plan, their task is usually to pick a packaging countermeasure and hope for the best. This is due to the lack of clear strategic direction from executives or even information such as simple risk assessments. Suddenly, packaging managers must be both tactician and strategist for the entire enterprise. Fortunately, risk mitigation is not completely alien to packaging professionals.

The base process of analyzing counterfeit product risk and selecting effective countermeasures should be familiar to packaging professionals. For example, a packaging professional may be responsible for the shelf life of a food product. But the first step to double the shelf life of a food product is not to just double the thickness of the package. The package designer must first understand the nature of how the products spoil (food science and biology), the product environment (chemistry and physics), the performance characteristics of the package (material science), and how these all interact (packaging science). Only then can a logical and efficient packaging design be tested and produced. Similarly, the selection of an effective anti-counterfeiting packaging component requires a multidisciplinary approach, but with some new disciplines based on the behavioral sciences that are focused on the details of the fraud opportunity.

Behavioral sciences and criminology primer

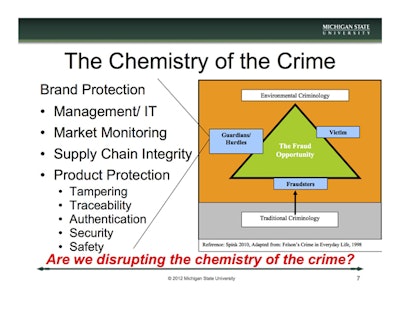

A key in the interdisciplinary approach to anti-counterfeit strategy is found within behavioral sciences and criminology. By understanding the root crime opportunity, companies and law enforcement authorities are able to identify why a crime took place or why a criminal might act. The application of Situational Crime Prevention is the Crime Triangle (see chart). The Crime Triangle requires three elements for a crime or the potential of a crime to occur. These are a victim (e.g., consumer, retailer, brand owner, etc.), a criminal, and the absence of a capable guardian or hurdle (e.g., inspectors, investigators, and traceability or authentication components).

As companies grow and their brands become more recognized, the victim side of the triangle will increase equating to a higher fraud opportunity. Regarding the criminal side of the triangle, there are a near-infinite number of criminals who may find counterfeiting opportunities. They are also difficult to deter because they are adaptive, creative, intelligent, resilient, clandestine, stealthy, and actively seeking to avoid detection. After a fuller understanding of criminals and victims, the main focus for brand owners should be on the guardian and hurdle side of the triangle. This will lead to the selection of countermeasures, including testing protocols and packaging tactics, which will effectively reduce counterfeiting opportunities.

Regulations, standards, and certifications

Another key to understanding the counterfeiting threat is common terminology. Standards and certifications are needed to provide common definitions and improved understanding. The International Standards Organization (ISO) created Technical Committee 247 on Fraud Countermeasures and Controls (TC 247). This group is specifically focused on fraud related to “material goods.” The group has begun to create management standards, which are general ways for securing systems. The group also is creating a Terminology document to assist in global harmonization. A related standard that is helpful is ISO 31000 Risk Management. Other groups are also involved in supporting different aspects of standardization such as the U.S. Pharmacopeia (USP), the North American Security Products Organization (NASPO), the Global Food Safety Initiative (GFSI), and Global Standards One (GS1) among others. These types of standards can lead to a certification of compliance.

There are also a variety of regulations related to counterfeiting. While necessary, there has been an over-emphasis on meeting regulations that haven't been fully defined with respect to their application. When a new regulation is passed, invariably suppliers scramble to maintain their competitive edge by developing new solutions. Brand owners also work to interpret the regulation so they can efficiently meet its requirements. Unfortunately application requirements of new regulations typically are not finalized quickly. For example, the 1987 Prescription Drug Marketing ACT (PDMA) is still in the process of having its traceability requirements defined. The California State Board of Pharmacy also pursued this but continues to delay e-pedigree implementation. Suppliers and brand owners alike initially scrambled to prepare to meet both regulations.

Another example is the 2011 Food Safety Modernization Act (FSMA). Although there are some well-defined product fraud statements in the act, and FDA finished the documents early, the guidance documents that define implementation have been delayed for months. The focus on meeting new regulations and certifications creates an initial sense of urgency and decision makers are generally not conditioned to wait. Ironically, waiting is one way to efficiently meet the regulations without making costly missteps. But at the same time, businesses cannot afford to ignore the existing risks from counterfeiters.

As simple as it may sound, remaining focused on protecting the business is an effective strategy. Regardless of PDMA and FSMA, pharmaceutical and food companies are currently exposed to immense vulnerability from counterfeiting, diversion, smuggling, cargo theft, organized retail theft, product fraud, and food fraud. While ultimately meeting these regulations is important, protecting the business is more urgent and actionable. As with all emerging business strategies, the challenge is how to get top management buy-in.

Beyond top management buy-in

An all too common mantra from operational managers or suppliers is “we need top management buy-in.” To address this perennial need, the School of Criminal Justice and the Business School at Michigan State University (MSU) have a research project underway that expands from “companies with high risks have a high risk mindfulness” to “how do companies achieve risk mindfulness.” Obviously extreme events raise awareness but that does not always lead to action or extended actions. Unfortunately the urgency of a risk often wanes over time and executive attention moves on to more visible and pressing issues.

Another MSU research project explores the aspect of vulnerabilities being “voluntary” or “involuntary” including the perception of control and authority. The case study research specifically explores the awareness of seafood fraud and whether respondents think that government or the private sector should control the threat. The risk mindfulness and continuing resource allocation is achieved when the threat can be clearly identified and the countermeasures explained. That is, clearly defined in financial or accounting terms.

The following steps aim to help packaging managers select effective countermeasures as part of a well-designed anti-counterfeiting strategy.

• Step one: Deconstruct the fraud opportunity for specific incidents

At the core of explaining vulnerability is deconstructing the fraud opportunity in detail. Only after explaining why and how a system is vulnerable can specific countermeasures be identified and selected. Descriptions should specify what type of criminal would violate specific systems including their potential method(s) of attack. Instead of using general terms such as “threats to brand equity,” explicit examples should demonstrate how vulnerability leads to recalls, dangerous product, lost sales, or lower market prices. Utilizing the crime triangle is an effective tool in deconstructing the fraud opportunity.

• Step two: Present risk and vulnerability in managerial and financial accounting terms

While packaging managers are in businesses, they are not necessarily from the academic discipline of business finance. Their expertise and education is primarily in the operational areas of food safety, packaging, materials science, engineering, product protection, corporate security, or procurement. Because corporate financial groups ultimately control expenditures, it is critical to translate counterfeit risk into their terms. While Enterprise Risk Management systems exist and are often ready, willing, and able to tackle the counterfeit risk, they do not necessarily translate vulnerability into accountant or financial management terms. Packaging professionals should seek to understand the exact financial models and terms their organization uses to evaluate the threat to the business and make allocation decisions. Utilizing enterprise risk management terminology is a good start.

• Step three: Understand the regulations and standards but focus on protecting the business.

Packaging professionals are often trained in process and quality improvement programs that narrow the focus to key factors that reduce vulnerability. While such focus may be efficient for root cause analysis and refinement of operations, it may be the wrong method to address emerging or evolving threats. When we narrow the focus, we test fewer places, which gives rise to more opportunities for counterfeiters to act and not be detected. Having too narrow of a product counterfeiting focus can be inefficient at best and catastrophic at worst.

Anti-counterfeiting standards and certifications will continue to evolve and provide effective best practices. Efficiently meeting emerging laws and regulations will continue to be important, but they should not be a distraction to existing business risks. Understanding impending regulations and standards are important but there must be a focus on mitigating specific business threats that may already exist.

• Step four: Continued vigilance of evolving fraud opportunities

So, what is next? No one really knows except for the would-be fraudsters. Again, fraudsters are clandestine, stealthy, and actively seeking to avoid detection. They are intelligent, resilient, often well funded, and their economic incentive can be astronomical. The counterfeiting threat grows and morphs everyday. The good news is that companies are achieving risk mindfulness and making well-reasoned decisions. Standards and certifications are being developed as regulations begin to be implemented. Industry, agencies, associations, and academics are coming together to understand the problem. They are developing efficient ways to communicate risk and vulnerability to executives, and create interdisciplinary systems that both detect and deter criminals.

Clearly a holistic all-encompassing approach is required. As the FDA described it, there is “no silver bullet”—or single packaging countermeasure that will solve the problem. Understanding the counterfeit problem begins by realizing that combating criminals is a process and not a destination. Packaging components are a critical part of an anti-counterfeiting strategy, not only in that they detect product fraud, but also deter counterfeiters.

—Article by John Spink, MSU A-CAPPP, PhD ([email protected]), Douglas C. Moyer, CPP, PhD-ABD ([email protected]), and Justin Heinonen, PhD ([email protected]). Visit the Anti-Counterfeiting and ProductProtection Program (A-CAPPP) and Michigan State University booth at PackExpo.