Key Takeaways:

· Rising demand for rigid plastic packaging across various industries is driving market growth.

· Its durability, resistance to impact, and ability to preserve product freshness make it a popular choice.

· However, the high cost of recycling rigid plastic products poses a challenge.

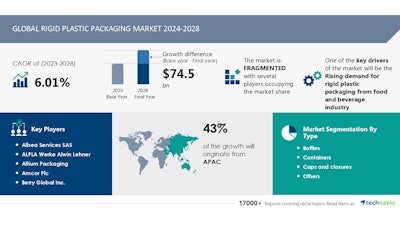

The global rigid plastic packaging market size is estimated to grow by $74.5 billion from 2024-2028, according to Technavio. The market is estimated to grow at a CAGR of 6.01% during the forecast period. Rising demand for rigid plastic packaging from food and beverage industry is driving market growth, with a trend towards use of fiber-based material for packaging. However, high cost of recycling rigid plastic products poses a challenge.

The rigid plastic packaging market is witnessing significant growth in various sectors including food, personal care products, and pharmaceuticals. Key materials like Polystyrene (PS), Polyethylene Terephthalate (PET), Polyvinyl Chloride (PVC), and Expanded Polystyrene (EPS) dominate the market.

Sustainability is a major focus with increasing recycling rates and advancements in recycling technologies. Eco-friendly packaging made of bioplastics is gaining popularity.

Market Challenges

- Rigid plastic packaging recycling involves significant costs for small and medium-scale manufacturing facilities. This is due to expenses such as procurement of used plastic, energy consumption during cleaning, crushing, and melting, and payment to scrap collectors. The collection and cleaning process alone requires a considerable amount of water and time. Moreover, most rigid plastic manufacturing units are designed for new plastic production only, leading to additional costs for recycling. In the food industry, for instance, a large percentage of rigid plastic wastes are discarded without cleaning. Consequently, the high costs and time required for cleaning and processing collected rigid plastic materials pose a challenge for the global rigid plastic packaging market.

- The Rigid Plastic Packaging Market faces several challenges in various industries. Strict government regulations in the medical, personal care, pharmaceuticals, and healthcare sectors pose challenges for packaging manufacturers. E-commerce sales and online retail necessitate product safety and customizable packaging solutions. Stringent regulations also apply to packaging materials in sun care, skin care, oral care, perfume, body care, and ornamental cosmetics. Adhering to government restrictions while maintaining product quality and innovation is a significant challenge.

Bottles

The Rigid Plastic Packaging Market is experiencing significant growth due to its numerous advantages over other packaging materials. Its durability, resistance to impact, and ability to preserve product freshness make it a popular choice for various industries. Additionally, the recyclability of rigid plastic packaging aligns with sustainability initiatives, enhancing its market appeal. Companies continue to invest in research and development to improve the material's properties and create innovative designs, further expanding its applications.

Research Analysis

The rigid plastic packaging market is a significant sector in the global plastics industry, with key materials including Polypropylene (PP), High-density polyethylene (HDPE), and Polyethylene terephthalate (PET). These plastics find extensive applications in various industries such as food and beverages, agriculture, aerospace, medical, consumer goods, and others. In the medical sector, it is used for packaging medical equipment and pharmaceuticals. Consumer goods, including cosmetics and toiletries, also utilize rigid plastic packaging. PET is widely used for sun care, skin care, oral care, perfume, body care, ornamental cosmetics, and hair care products. Recycling rates for rigid plastic packaging are increasing, with extrusion, injection molding, blow molding, and thermoforming being common manufacturing processes. Fiber-based materials are also gaining popularity as sustainable alternatives.