Polyvinyl Chloride (PVC) and Bi-axially Oriented Polyamide (BOPA) films have been the go-to for cold-formed pharma packaging, but with them come a host of problems. Traditional blister packs are harmful to the environment as they yield chlorine when coming in contact with sunlight. PVC leaves a high carbon footprint and its plasticizers and phthalates are linked to health disorders that can damage the liver, kidney, lungs, and reproductive system. BOPA faces its own challenges like high moisture absorption (8-10%), which makes processing difficult and delamination an issue.

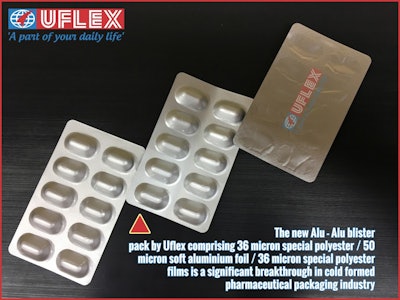

A recent article from Money Control says these issues could be a thing of the past thanks to an innovative packaging solution from India’s Uflex. Engineers at Uflex’s Films Business spent nearly two years developing a polyester film to replace the top and bottom substrates of conventional cold-formed Alu-Alu laminate. The special polyester sandwiches the aluminum foil layer with optimal barrier, clarity, printability, and hardness properties. The engineers have also applied metaphase morphology making it possible to form the material in the Z direction, a prerequisite of blister packaging.