Pharmaceutics International, Inc. (Pii) is looking beyond the regulatory horizon and moving lightning-fast to meet the requirements of tomorrow. Functioning at this leading-edge means that the Hunt Valley, MD-based Contract Development and Manufacturing Organization (CDMO) continuously adopts the latest in best practices.

Those include manufacturing capabilities that have helped Pii grow to upward of 250 scientists and supporting staff since its beginning in 1994. The science-driven company provides dosage form development and cGMP manufacturing services to the global pharmaceutical industry, catering to major multinational and virtual pharmaceutical companies worldwide.

The CDMO’s 430,000 sq-ft of space at its U.S. facilities contain more than 70 manufacturing rooms, as well as containment suites for handling high-potency compounds and hormones, dedicated manufacturing suites for soft gels and injectables, a formulation development center, and analytical laboratories.

Pii’s facilities are inspected by both the FDA and EMEA and are registered with the DEA (schedules I-V).

Last year, Pii installed flexible track-and-trace systems from Mettler-Toledo PCE to two bottle filling/packaging lines. Within the next month or two, Pii also expects to be serialization- and aggregation-ready on two cartoning lines. One of these is for placing labeled vials into cartons, the other for packing blister cards into cartons.

“This project was all about getting serialization-ready,” says Koshy George, Associate Director of Validation and Technology Transfer at Pii. “We looked at the solutions available on the market and considered efficiency, versatility, cost, and the size of our production levels. We decided that Mettler-Toledo PCE was the best supplier for our current and future needs.

“On top of that, we have equipment from Mettler-Toledo on the production side of our facility, and we’ve always had great experiences with their customer service. That kind of help is especially important for our first serialized lines.”

Alex Chase, Pii’s Validation Associate, points out, “Since track and trace was a new technology for us, we appreciated that Mettler-Toledo PCE was able to provide all of the required support, from purchasing to commissioning of the equipment. Our teams were able to work effectively together to implement this new technology. Mettler-Toledo helped along every step of the process, and the PCE equipment has been great.”

Chase adds, “Installation was very simple. Our existing equipment, like bottle labelers and printers, were integrated with these new solutions without any trouble.”

Serialization and aggregation

The PCE-equipped lines at Pii are capable of serializing and aggregating bottles, cartons, bundles, cases and pallets. On the two bottle packaging lines, variable data is printed on the label web before the labels are applied to bottles.

On the soon-to-be installed two cartoning lines, un-serialized bottles, vials for injectable products, or blister cards will be packed into cartons, with serialized data printed directly on cartons. One station on each line will enable manual aggregation at every step. Serialized bottles or cartons can be aggregated directly into cases or into bundles and then cases. Subsequently, all cases will be aggregated into pallets for shipping.

“Our customers’ needs vary widely, and, thanks to the flexibility of the PCE solutions, we can do it all,” says Chase. “We make so many different products in many different bottle sizes, ranging from 40 cc to 400 cc. Each line needs to change over quickly and easily. Line changeovers can take anywhere from four hours to a complete day, with those times including all required cleaning and testing. Equipment changeovers are usually completed within one to two hours. Customers also require different levels of aggregation. Some are bundling cartons and some are not. Flexibility is essential for us.”

Cloud-based program

At Pii, serial numbers, product, order and line information are managed by a central repository, the PCE Site Manager Level 3 software, which is connected to TraceLink, a multi-tenant cloud program that enables two-way communication between Pii and its customers. This includes sending and receiving serialization and aggregation data.

The PCE Site Manager is integrated with each line via PCE’s Line Manager Level 1-2 software. PCE Line Manager controls order information on the line, including product data, packaging formats and serial numbers, with communication to intelligent devices on the line that includes PCE cameras, scanners, printers, labelers and reject mechanisms.

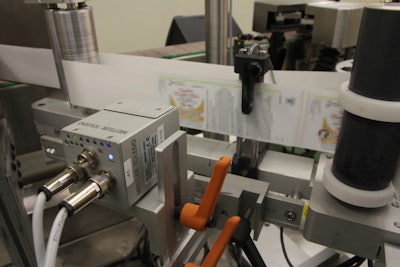

For instances when bottles are the saleable unit, each line at Pii is equipped with a Label Serialization Kit from Mettler-Toledo PCE installed on a bottle labeler to produce serialized labels using a thermal-transfer printer with data provided by the PCE Line Manager software. Labels are then inspected by a PCE smart camera, with only approved labels applied to the bottles.

“We like that this technology was able to be installed on the labelers that we already owned, since we were familiar with them,” notes Chase.

Downstream packaging

To make cartons the saleable unit, Pii operates two PCE datamatrix stations, one of which is portable, allowing it to be moved as needed for flexibility. On each system, cartons are placed on the infeed conveyor, and serialization information is printed directly on the cartons with an inkjet printer.

A PCE smart camera inspects the data for accuracy and quality, and a PCE pneumatic reject device removes the carton if there are any errors. For extra security, a lockable bin holds rejected cartons. Only approved employees have access to remove and properly dispose of packages with errors.

Says Chase, “We appreciate how compact our datamatrix systems are. Floorspace is at a premium in our facility, especially in our blister and vial packaging rooms where we are adding serialization soon.”

Next, each line features a single PCE Manual Aggregation Station, which enables Pii to aggregate bottles or cartons to bundles, cases and pallets. When packing serialized bottles directly into the case, the operator scans the 2D codes on the bottle labels to record the serial data. Parent-child relationships of 12 or 24 bottles are created, depending on the case size, and the printer generates a serialized case label.

The same process is followed when packaging serialized cartons into cases. For bundle aggregation, individual bottles or cartons are scanned to record the serial data and a serialized bundle label is generated. The final step is all serialized labels are aggregated to pallets with a unique serialized pallet label.

“We wanted manual aggregation systems, because they’re so versatile. This solution is perfect for our needs,” says Chase. “PCE’s software is very intuitive and straightforward, from general operation and changing over to troubleshooting. Each line has an identical user interface, so it’s easy to train and move operators. We also use multiple security levels for 21 CFR Part 11 compliance. Operators are restricted to starting and stopping the systems and can’t accidentally tamper with the settings.”

Beyond the system’s benefits, Chase explains that Mettler-Toledo’s customer service is an important piece of the serialization puzzle. “It’s normal to have a few questions pop up after installing new technology, and their technicians are always readily available to help us sort it out,” he says. “We’re still in close contact with our Mettler-Toledo team, because we’re working with them to add track-and-trace capabilities to more of our packaging lines. They clearly explain our options, and we appreciate their expertise and insights.”

Looking at the “big picture," Koshy says, “We had a long list of requests and limitations for our first serialization and aggregation solutions. Mettler-Toledo PCE identified the ideal technologies for our situation and seamlessly integrated them with our existing packaging equipment. This project is a great success. We’re ready for the upcoming regulatory deadlines.”