This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Capable of fitting restrictive processing situations, the Flexicon mobile tilt-down flexible screw conveyor offers a low center of gravity and full accessibility from standing height.

Positioning the support boom against and parallel to the conveyor tube minimizes the height needed to maneuver the system under doorways and mezzanines, and to fit the conveyor’s discharge between process equipment inlets and overhead obstructions. A low center of gravity maximizes stability during operation and when rolling the unit between multiple processing tasks and washdown stations.

When fully lowered, the tilt-down mechanism positions the clean-out cap of the conveyor tube higher off the plant floor, and the conveyor’s discharge closer to the floor, allowing removal and re-insertion of the flexible screw from standing height during cleaning and inspection.

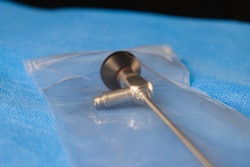

The screw is the only moving part contacting material, and is driven beyond the discharge point, preventing material contact with bearings or seals. It self-centers as it rotates, providing ample clearance between itself and the tube wall to eliminate or minimize grinding, while creating a gentle rolling action that prevents segregation of the most disparate blends.

Constructed of 316 stainless steel finished to sanitary standards, the mobile system is equipped with a low-profile hopper with bag support tray; quick-release clean-out cap; quick-disconnect discharge access cover; and stainless control panel, conduit, and liquid-tight compression fittings, allowing washdown and/or conveying of corrosive materials.

Ready to plug in and run, it includes HMI controls for manual or automatic start/stop and speed adjustment, and a manual hydraulic jack to raise and lower the support boom and conveyor assembly. A range of screws with specialized geometries is available to handle free- and non-free-flowing materials, including products that pack, cake, or smear.