This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

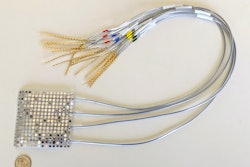

Medical catheter manufacturers throughout the world use Dunn’s Catheter Cores to retain critical lumen tolerances during the manufacturing (extrusion, braiding, coiling and jacketing) of minimally invasive catheter shafts. Low friction material properties and ultra-smooth surfaces allow these mandrels to be easily removed after catheter shaft assembly. They are available in precise diameters from 0.020 to 0.250 inches with tolerances as low as +/- 0.0005 inches.

Dunn also manufactures custom medical tubing for diagnostic and interventional devices from a wide range of thermoplastics. These include polyether block amides (PEBAs), thermoplastic polyurethanes (TPUs), thermoplastic elastomers (TPEs), polyamides, polyolefins and much more. Tubes are available with diameters as small as 0.008 inches (outer diameter) x 0.004-inches (inner diameter), and diameters as large as 0.480 inches. Configurations include single and multi-lumen, coextruded layers and stripes, and longitudinal wire or fiber reinforced.

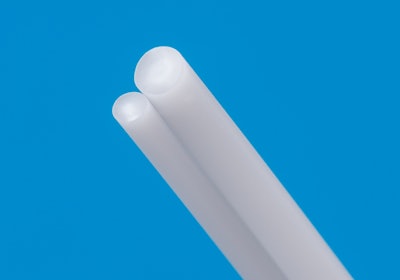

Natvar’s new silicone tubing capability range features an inside diameter of 0.2-25 mm (0.0079-0.984 inches), with wall thicknesses ranging from 0.10-3.0 mm (0.0039-0.118 inches), and tolerances as low as +/- 0.03 mm (0.001 inch). This newly expanded range of Natvar single-lumen silicone tubing is intended to better serve a range of medical pump applications, including peristaltic and patient-controlled analgesia (PCA) pumps.