This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

At SupplySide West, October 6-10 in Las Vegas, Pharma Technology Inc. will display at Booth #21007 two machines whose common differentiator is vertical height gain, which yields the possibility of needing only one operator rather than two. Offering premium levels of capsule polishing and dedusting, the PTG-V Vertical Capsule Polisher handles capsules at speeds up to 500,000/hour. Each of the PTG-V line’s three models is fully mobile, offers quick tool-free dismantling and reassembly, and occupies minimal floor space. In addition, each can be dismounted without tooling, and cleaned via ultrasonic wave bath.

A polyamide/nylon rotary screw endless brush achieves polishing of scratches and blemishes on the capsule surface inside a 316-liter stainless steel cylindrical section. Suction stitches positioned throughout the length of the uphill conveying device also allow powder excess to be thoroughly removed. Each of the PTG-V Vertical Capsule Dedusters can be equipped with an empty capsule eliminator device (ECE). This guarantees, with 100% accuracy, that production is completely devoid of empty, broken or half capsules.

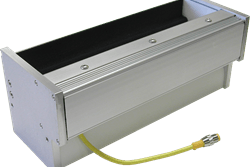

Also on display at SupplySide West will be the EconoFlex Vertical Tablet Deduster. Designed for the dedusting and deburring of all tablet types, EconoFlex features a high pressure-molded polymer spiral composed of FDA-accepted material with a closed face surface (0.5µm RA) that does not scratch or discolor and is resistant to heat and alcohol. The high-tech materials and innovative design allow dust extraction to take place on the spiral’s outer circumference, as close as possible to the path of the tablets for optimized dedusting. The result is a higher dedusting capacity compared with traditional units.

EconoFlex's spiral segments are stackable and dismountable for versatility and ease of use. This spiral system also affords varying gains in height, allowing for discharge after dedusting/metal detection in taller containers or drums at least 30” off the floor. The machine's noise level is low, and clean-up is tool-free. EconoFlex also can be combined with metal detectors, which are also available through Pharma Technology Inc.

At INTERPHEX Puerto Rico, October 16-17 in San Juan, Pharma Technology Inc. will showcase an enhanced in-process tablet tester for its AIO - All In One Tablet Deduster and Tester System. Short for “All In One,” the AIO Deduster and Tester System builds upon the company’s signature PharmaFlex family of dedusters by offering turnkey peripheral devices as integrated solutions. The system’s sophisticated engineering affords unparalleled flexibility while meeting superior standards for output and quality of dedusting.

Pharma Technology Inc.’s AIO Deduster and Tester System combines three units on one fully-GMP base. First is PTI’s PharmaFlex segmented deduster spiral, which is composed of high-tech pressure molded polymer segments or 316 stainless segmented spiral (each stainless segment has a vertical height of 500mm). Second is one of the company’s three main pharmaceutical models of metal detector: Ceia, Lock or Safeline.

The third component is a high-precision, in-process tablet tester for weight, thickness, diameter and hardness. The AIO’s tester now offers these unique features:

-

Vacuum transfer (as opposed to Venturi) and filter providing dust-free transfer of samples to tester

-

Tool-free dismantling of all product contact parts, for easy cleaning

-

Dust-tight segregation of technical areas

The tester can be positioned on any of three sides on the deduster’s base, and offers push-fit cable-free connections for power and data storage. This creates a compactness where the need for additional vacuum conveying pipes and cables has been eliminated. The tester also contains an advanced scale generation that eliminates most manufacturing interference. The result is streamlined performance of tableting machinery – a means of directly monitoring and controlling the manufacturing process with significantly less operator supervision.