Ampac will be relocating its Chicago area pouching facility, currently located in Elk Grove Village, to a larger location approximately 10 miles west to Hanover Park, Illinois. This new facility will allow for a more efficient layout of the plant, as well as provide additional space for growth of Ampac's pouching business.

With the help of commercial real estate firm Cushman and Wakefield, brokers Si Pitstick, based out of the Cincinnati office, and Britt Casey from the Chicago office were very helpful in the selection process, lease negotiation and selection criteria for the new building. The Elk Grove Village site has experienced steady growth over the past five years, which included one expansion to the building. Because there is no room for future expansion, the facility will be moved to the new Hanover Park location. After the move, the plant footprint will increase by approximately 50,000 square feet at the new site. The new location will be a state-of-the-art pouching facility specifically designed as a pouching-only operation.

The move will take place during the second and third quarter of 2011 and is slated to be completed by October 1. It is expected that all current employees will transfer with the move with minimal disruption to the business.

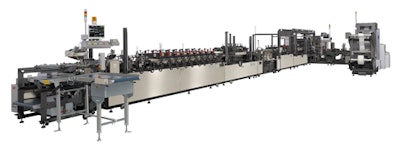

In addition to the move, the new Hanover Park facility will purchase a Totani BH-60DG-F (SG-6) Box Pouch® making machine at this year's Interpack Show in Dusseldorf Germany. This purchase is the third pouch format Ampac has added within the past twelve months to its line of Totani pouch machines that run E-Z ZIP®, including plow bottom and inserted stand up pouch. The new machine provides Ampac with the first machine globally, that has two-up box pouch capability. Ampac can produce the E-Z ZIP format in a two-up format while all other standard press-to-close zipper box pouch machines run a one-up format.

The Totani Box Pouch machine can be used in a wide range of packaging applications, including food such as candy and cereal, pharmaceuticals, household cleaning products and other liquids, pet food, medical bags, pouches and multi-pack pouch formats.

The machine has five panel registered print capability and can accommodate most laminated films used in pouches for food and industrial applications. A savings of approximately 12% in film is realized when compared to a conventional stand up pouch with the same fill capacity. Totani's technology realizes both high-speed box pouch making (up to 200 pouches/minute¬), as well as high-quality, high strength sealing which makes the box pouch suitable for storage and transportation of not only solids, but also liquids due to its high seal integrity.

With the help of commercial real estate firm Cushman and Wakefield, brokers Si Pitstick, based out of the Cincinnati office, and Britt Casey from the Chicago office were very helpful in the selection process, lease negotiation and selection criteria for the new building. The Elk Grove Village site has experienced steady growth over the past five years, which included one expansion to the building. Because there is no room for future expansion, the facility will be moved to the new Hanover Park location. After the move, the plant footprint will increase by approximately 50,000 square feet at the new site. The new location will be a state-of-the-art pouching facility specifically designed as a pouching-only operation.

The move will take place during the second and third quarter of 2011 and is slated to be completed by October 1. It is expected that all current employees will transfer with the move with minimal disruption to the business.

In addition to the move, the new Hanover Park facility will purchase a Totani BH-60DG-F (SG-6) Box Pouch® making machine at this year's Interpack Show in Dusseldorf Germany. This purchase is the third pouch format Ampac has added within the past twelve months to its line of Totani pouch machines that run E-Z ZIP®, including plow bottom and inserted stand up pouch. The new machine provides Ampac with the first machine globally, that has two-up box pouch capability. Ampac can produce the E-Z ZIP format in a two-up format while all other standard press-to-close zipper box pouch machines run a one-up format.

The Totani Box Pouch machine can be used in a wide range of packaging applications, including food such as candy and cereal, pharmaceuticals, household cleaning products and other liquids, pet food, medical bags, pouches and multi-pack pouch formats.

The machine has five panel registered print capability and can accommodate most laminated films used in pouches for food and industrial applications. A savings of approximately 12% in film is realized when compared to a conventional stand up pouch with the same fill capacity. Totani's technology realizes both high-speed box pouch making (up to 200 pouches/minute¬), as well as high-quality, high strength sealing which makes the box pouch suitable for storage and transportation of not only solids, but also liquids due to its high seal integrity.

Companies in this press-release