This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

tna’s proprietary sustainability calculator will also be available for visitors to assess how the use of single-serration jaws on vf/f/s packaging systems can help to reduce film consumption and enhance sustainability credentials.

“Our purpose is to help our customers to realize ambitious sustainability goals and create a greener, more prosperous world,” said Nadia Taylor, Co-founder and Director at tna solutions. “To cater for the growing aspirations of both brands and individuals towards a circular economy, we are very proud to apply our diverse capabilities and food industry experience to create solutions that improve the environmental footprint of manufacturing operations.”

The tna sustainability corner will also showcase the capabilities of the tna robag to run a range of industry compliant sustainable film materials. It also demonstrates an integrated line for snack producers featuring the tna robag® 3e, and the tna auto-splice 3 with EtherCAT® real-time protocol and an integrated display controller system.

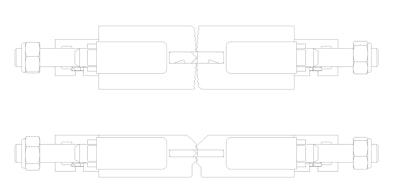

tna will showcase single-serration jaws (shown) that help to reduce the consumption of BOPP. The sustainability calculator, available throughout the show, allows snack producers to evaluate potential film savings. For example, single-serration jaws enable a 5-millimetre material saving per seal. On vf/f/s systems that produce 150 bags/min, these savings translate into 2.26 million bags per month. In a factory of 10 packaging lines, operating at least 12 hours a day, it results in almost 390 kilometres of film saved a month.