If you’re concerned about your pharmaceutical serialization efforts, you’re certainly not alone. Despite the limited time left meet upcoming 2017 serialization mandates, industry experts and organizations such as the European Medicines Verification Organisation (EMVO) continue to convey apprehension that companies are not ready for serialization and Falsified Medicines Directive mandates.

A common theme among serialization discussions is the worry over potential drug shortages if manufacturers are not prepared in time. This is alarming for regulators, industry and, most of all, the patients who depend on life-saving or life-enhancing treatments.

According to Pharma IQ's recent Pharmaceutical Serialisation and Traceability 2016 report, 25.7 percent of participants have started serialization rollout across multiple sites, and only 13.5 percent have fully implemented their approach. "Almost everyone thinks they will be fully ready within 24 months, which seems optimistic bordering on unrealistic," said Mark Davidson, CEO of Bluesphere Health.

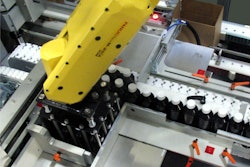

For pharmaceutical manufacturers looking to add serialization and aggregation before the 2017 deadline, machinery integrated with serialization technology can help cut down on implementation time. Along these lines, ESS Technologies, Inc. has integrated its Model V30HS High Speed Robotic Case Packer with off—the—shelf serialization equipment for a compact, fully automated system for aggregating and serializing case contents during the case packing process.

The technology offers flexibility for many pharma manufacturing processes, as it can accommodate bottles, cartons, bundles and blisters. The V30HS uses a FANUC M‐20iA robot for case loading, and is integrated with Optel Vision’s 360° Camera System at the infeed. Bottles are labeled with unique ID codes and scanned (up to 400 bottles per minute) as they enter the servo collation area. The machine automatically forms the correct pack pattern while simultaneously erecting an RSC case and placing it in the loading position.

An Optel Vision overhead camera verifies that the case is fully loaded before the V30HS seals the case on the top and bottom. Incorrect cases are automatically rejected from the system. For correctly loaded cases, information about the bottle codes is transferred from the serialization PC to an integrated case labeler that prints the required serialization code and applies the case label. A final Optel Vision scanner verifies the printed label before the case exits the system.

To offer additional flexibility, there are options for closures (standard tape or glue) as well as integration with a checkweigher. The system can accommodate 2-layer pack patterns, and the robot can be programmed to add medguides or booklets to the case.