This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

The latest advanced automation technology system from CBW Automation will make its debut at the upcoming K Show 2016, October 19-26 in Dusseldorf, Germany, running the latest advancement in packaging – the Klear Can – in a Ferromatik Series 280 In-Mold Labeling (IML) injection molding system from Milacron in Hall 15/C06.

CBW Automation Inc., a recognized leader in customized automated custom packaging systems for high-speed, high-volume production injection molding and thermoform packaging lines, was chosen to help showcase the Klear Can IML production system at K because of the company’s advanced automation technology. The new Advantage Series automation system provides customers with the most innovative automation solution yet. The new Advantage Series provides an alternative system that promises high performance, manufacturing flexibility.

“The innovative modular design of the Advantage Series allows for commonality between the majority of systems components,” says Robert Harvey, Vice President – Sales and Marketing for CBW. “These economies of scale result in cost benefits for the customers. As well, stocking these common parts will allow for very rapid delivery of standard executions, even as quickly as 6-8 weeks.”

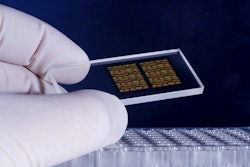

Milacron’s Klear Can is a recyclable multilayer plastic can that is poised to dethrone metal food cans for the packaging of long shelf-life items such as fruits, vegetables, fish, meats, and more. Milacron recently confirmed the sale of the first Klear Can production system, with Klear Cans expected to hit grocery store shelves in Q1 2017. The Klear Can offers the clear advantage of allowing the consumer to see the quality of the food at the point of sale in a BPA-free package. For brand owners, the Klear Can offers the added advantage of allowing the can to run in existing filling, seaming and retorting lines at canneries. Labels for the IML system are provided by Verstraete IML technologies.

CBW provides an engineering evaluation of each project that customers bring to them to enable the company to determine the best customized solution to meet customers’ specific needs to fit every application. CBW’s current products include the TS-303 which offers the fastest retrieval on the market; the TSE with reduced footprint and high flow part capture; and the SSE that offers strip stroke with high flow part capture. CBW also offers an extensive package of downstream systems. From complex downstream operations to simple stacking, CBW has a solution backed by over 30 years of experience.

Designed with customers’ feedback and requirements in mind, CBW’s new Advantage Series automation continues the long-standing CBW tradition of proven performance, reliability, optimum productivity, and reducing costs and improving quality of its previous systems, while retaining the same intrusion time that CBW customers expect while employing a new strategy for parts retrieval.

For more information, click here