Capsule and tablet weighers play a critical role in highly regulated pharmaceutical production, ensuring accurate dosages are packaged to be delivered to patients in need.

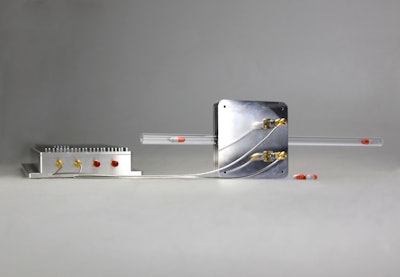

At PACK EXPO 2022, Work Microwave, which is a Germany-based developer and manufacturer of RF electronics technologies and products, showed its WORKsens FT-96 Pharmaceuticals Weight Measurement Sensor.

The sensor is based on the microwave resonance method and it’s small enough to be integrated into a filling machine directly to characterize the weight of capsules and tablets in continuous production systems.

With traditional checkweighers, there’s a limit to how fast products can move through machines. As product manager Lukas Lischke explained at the show, conventional load cells in pharma checkweighers require that the individual tablets or capsules be at a standstill for a brief period of time for accurate measurement. The systems based on gravitational force are also sensitive to vibration, so checkweighers must be heavy machines (often ~1,000kg) to remain stable in the face of vibration on busy production floors. Most operations also require a lot of load cells to achieve the throughput pharma companies demand.

With the WORKsens FT-96, tablets or capsules flow through a duct tube of 12 mm outer diameter and are measured one at a time without stoppage at up to 15 capsules per channel per second. Units are compact, so they can be stacked to run in parallel for higher throughput.

“As it's based on RF microwave detection, the capsules can go in freefall—you don't need the stopping moment or the one square meter of floor space that traditional checkweighers require,” Lischke said. “It can integrate directly into another company's filling machine, for example, and create a closed-loop cycle without a big distance. If 500 capsules pass through a distance before an error such as a clogged nozzle is detected, then you have to throw away everything that's in between. Here, your loop cycle is way quicker because your distance is way shorter.”

More details in the video: High-speed capsule and tablet weight measurement on the fly

As the company reports, “A data acquisition platform attached to the sensor head permanently monitors the resonator head for changes in product properties. This allows the sensor to detect if pharmaceutical tablets are fully intact or exhibit defects, with the option to reject under- or overfilled capsules or cracked tablets.”

The sensor must be calibrated for each capsule. For a CMO or brand owner running a variety of tablets, they would calibrate the system initially before running a new product. After each initial calibration, there is no further recalibration required on product changeovers.

Potential applications

The WORKsens FT-96 was a finalist in the PACK EXPO International 2022 Technology Excellence Awards in the "Personal Care/Pharma" category. The sensor has the ability to harmonize with new digital Industry 4.0 concepts and has potential for continuous manufacturing of pharmaceutical products down the road, not just for its speed, but as a sensor that will help companies identify process drift or product issues in near real-time.

The sensor has a range of potential applications for weighing small products that require accuracy that are non-conductive. While the demo on show was for oral solid dose drugs, Lischke said the technology could even be applied to syringe and vial filling systems.

“We can build a resonator in a way that it is a fixture of the wheel already, and you can monitor the filling process from the empty bottle up to the correct filling weight,” said Thomas Wiesner, regional sales director.

As drugs become more and more potent, and their volumes become smaller and smaller, companies must maintain filling accuracy both for regulatory needs and patient safety. “There are some applications where the filling volume is very, very small. Sometimes the filling weight is smaller than the tolerance of the single dose vial. In that situation, you cannot measure it anymore with a typical scale. But this system can detect low weights because you only measure the difference between the empty and filled single dose vial,” explained Wiesner.

“Sometimes you even have droplet measurements—if you want to add specific volume by droplets. You can let those droplets fall through the resonator and you can measure the volume of each falling droplets,” added Lischke.

Next steps

WORK Microwave is currently looking for beta testers, as the system is not GMP- or FDA-compliant yet. So, while a company cannot use this on the last step of their line for compliance, checking, and record creation, it can be used as a feedback system on a filling line to close the loop quicker. “You still need a conventional checkweighing system at the end of the line at the moment because the FT-96 is not yet compliant. Currently, we’re looking for partners to run our system in parallel with conventional load cells for case studies that show we are as accurate or even more accurate than conventional load cells for each type of product,” said Lischke.