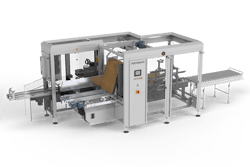

Part of the MULTIVAC X-Line packaging technology is a process that assists in the digitalization of configuration and performance according to Industry 4.0/IoT standards. Seamless digitalization, comprehensive sensor systems, and networking with the MULTIVAC Cloud can significantly improve packaging reliability, quality, and performance.

Under the title of Smart Services, MULTIVAC offers packages that contribute to a deeper understanding of the performance of the packaging machine. Providing valuable data which can be used to further optimize packaging procedures and make them even more efficient:

• Smart Production Dashboard—Provides real-time data of the day’s production run with historical information displayed for reference.

• Smart Machine Report—Supplies the user with automatically generated monthly reports on the machine performance.

• Smart Log Analyzer—Offers the user an opportunity to review relevant machine triggers that hamper performance to assist in improving processes.

• Smart OEE analyzer—Presents the user with historical data on the machine’s availability, performance, and quality.

MULTIVAC Pack Pilot allows access to comprehensive expert knowledge and makes it possible to set up a new packaging solution at the optimum level when a new film is introduced to the machine. This produces packs with maximum packaging reliability, consistent quality, and very high output without production loss while trying to establish the correct machine settings for that film. This leads to significant savings in products, materials, and production time.

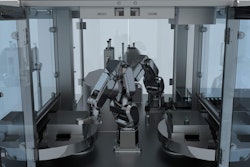

MULTIVAC Multi Sensor Control is constantly adjusting the machine settings to work very close to the optimum operating point at all times. Any deviations from this, whether conditioned by product or by the system, are automatically compensated wherever possible. The Multi Sensor Control enables many quality problems to be prevented.

MULTIVAC HMI 3 is an intuitive, high-resolution, multi-touch user interface that corresponds to the operating logic of today’s mobile devices. It enables the operating processes to be controlled even more easily and reliably. All the relevant machine parameters are displayed on one screen page.

PACK EXPO Connects – November 9-13. Now more than ever, packaging and processing professionals need solutions for a rapidly changing world, and the power of the PACK EXPO brand delivers the decision makers you need to reach. Attendee registration is open now.

A new die generation called MULTIVAC X-Tools features extensive innovations regarding design, sensors, and actuation elements. Moreover, the sensor modules are equipped with a status indication. Because of this, X-Tools contributes to increased cost-effectiveness in the packaging process.

MULTIVAC X-Map allows for accurate and reproducible gas flushing. This feature can be precisely controlled for packing with a modified atmosphere. It ensures all packages have the same final pressure, regardless of the volume of the product inside.

Go here for a PACK EXPO Connects demo on Zero-Downtime Labeling with the MULTIVAC L310. The event runs through Friday, November 13, and as of Wednesday PMMI reported it had attracted 17,000 attendees visiting the booths and viewing the demos from more than 700 committed exhibitors who are driving the show.