Show Daily Exclusive - Catalent Biologics, a leading provider of advanced delivery technologies and development solutions for biologics, works closely with customers from early development through commercial supply. To comply with serialization regulations, Catalent’s team in Bloomington, Indiana, turned to Mettler-Toledo PCE, part of Mettler Toledo (Booth C-2023) for affordable track-and-trace solutions, which could be easily added to their vial and syringe packaging suites.

Rebecca Book, senior process engineer at Cata-lent Biologics, recalls, “When we started researching serialization and aggregation solutions, our top considerations were compliance, cost, turnkey implementation, ease of use and customer service. We spoke with six . . . equipment suppliers, and Mettler-Toledo impressed us the most.”

“One of the biggest reasons we went with Mettler-Toledo PCE is they offer turnkey lines— they provide everything, from the equipment and software to integration and support,” explains Edward Krause, principal manufacturing specialist at Catalent Biologics. “Since all our track-and-trace solutions come from one supplier and have similar user interfaces, it’s easy to train operators and troubleshoot,” he adds.

The PCE-equipped line produces biologic products in vials from 2mL to 20mL and pre-filled syringes from 0.5mL long to 5mL standard. The vials and syringes are packed into cartons, and serialized data is printed directly on the side of each carton. Cartons can be aggregated directly into cases or first into bundles and then cases. Then cases are aggregated into pallets for shipping.

“We chose a mixture of manual and automated track-and-trace systems to maximize our production flexibility and enable us to easily scale as we further automate parts of the line,” says Krause.

To manage track-and-trace data, Catalent Bloomington installed PCE’s Site Manager Level 3 software, a central repository for serial numbers and other product, order and line information. The software interfaces with TraceLink, a multi-tenant cloud solution, for two-way communication between Catalent Bloomington and its customers. The Site Manager is connected to the vial and syringe packaging suites via PCE’s Line Manager Level 1-2 software, which sends order information to intelligent devices, including cameras, scanners and printers.

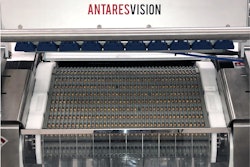

In terms of equipment, the first track-and-trace step happens immediately after vials and syringes are packed into cartons. Here, the fully automated PCE T2620 DataMatrix station marks serialization information directly on each carton with an inkjet printer, and a PCE smart camera confirms the data is correct. If there are any errors, a PCE pneumatic reject device removes the carton from the line. “This system is great. It’s user-friendly and has fantastic accuracy . . . ,” says Abbi Coleman, equipment lead at Catalent Biologics.

If needed, a PCE T2660 manual aggregation station aggregates cartons to bundles. The operator scans the 2D codes on the cartons to create parent-child relationships and record the serial information. A printer generates a serialized bundle label, and after the cartons are bundled, the label is manually applied.

To aggregate cartons and bundles to cases, Catalent Bloomington selected the multiple-code-reading PCE T2650 shipping case station. Instead of manually scanning each carton or bundle, an entire layer is manually packed into the case, and a PCE high-resolution camera scans the 2D codes on all the cartons or bundles in the layer at once. After the case is filled and all the parent-child relationships are created, the printer generates a serialized case label.

Cases then move to a second T2660 manual aggregation station, where they are aggregated to pallets for shipping. A third T2660 system, found offline, handles rework. “These incredibly versatile systems can handle our customers’ many products and package formats,” says Book. “We could actually aggregate at every step using a single manual aggregation station, but we chose to purchase three to increase our throughput.”

Just upstream of its PCE track-and-trace systems, Catalent Bloomington relies on an XS3 checkweigher with a pneumatic push-arm reject device, both from Mettler-Toledo Hi-Speed. By detecting any over- or under-filled cartons, it automatically removes any packages that may have missing or extra products or inserts. Approved cartons are conveyed to the DataMatrix station for serialization.

“At the end of the day, the most important thing is that we’re fulfilling our commitments,” says Laine Mello, marketing specialist at Catalent Biologics. “We have a responsibility to be the very best partner . . . these track-and-trace systems from Mettler- Toledo PCE are essential for our success.”

For more information, visit www.mt.com/pi. SD