The Better Bean Company, Portland, OR, positions its products as “all-natural, vegan, cholesterol-reducing, cancer-fighting, gluten-free, soy-free super foods.” Better Bean founder Keith Kullberg felt confident that his company had perfected the recipes for the bean line. The challenge then became to get consumers to notice the product. So Better Bean opted to revisit the round injection-molded monolayer polypropylene tub—which pretty much looked like everybody else’s tub—and redesign the packaging.

“With the old packaging no one noticed our product on the shelf. We even had difficulty finding it ourselves,” says Kullberg. So the primary objective of the package revamping project was to present a distinctive, high-shelf-impact container to showcase the premium-quality, locally grown line of deli-style beans, freshly packed for marketing in a refrigerated state.

While attending Pack Expo in September 2011, Kullberg met Jeffrey Best, director of marketing for Spartech Packaging Technologies. Spartech is a leading producer of plastic sheet, rollstock, plastic resins and alloys, and color and specialty compounds for a wide range of packaging customers. The firm is also the exclusive representative in North America and Mexico of some unique lidding technology from Sweden’s Arta Plast. At Pack Expo 2011, Spartech previewed this 1-Seal™ proprietary packaging technology for resealable tubs. The in-mold labeled (IML) lidding system caps and seals containers using a single component, thereby eliminating the need for separate foil or film membrane seals beneath the lids.

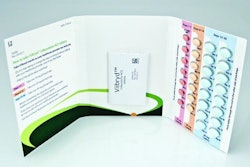

At the heart of the 1-Seal technology is a polypropylene film label that is integrated into the polypropylene rigid plastic lid while the lid is being formed in the injection molding tool. But a portion of the film label around the perimeter of the lid’s central panel does not have resin injection-molded onto it. This extended portion of the label remains exposed, so when the lid comes out of the mold it has a thick, rigid, injection-molded central panel surrounded by a thin film extension. It’s this film extension part of the unusual lid that gets heat-sealed to the injection molded monolayer PP tub.

Better Bean also opted for a tub made by Arta Plast and supplied by Spartech, but it is not the predictable round tub used previously. Instead it’s a rectangular container that also sports high-impact IML decoration. Spartech markets the total concept as its 1-Seal packaging system, which is heat-tolerant, microwaveable, freezer-to-microwave resilient, and 100% recyclable in polypropylene waste collection streams.

Great appearance

Kullberg likes the rectangular shape of the 1-Seal packaging system. “We like the four-sided IML label,” he notes. “It looks much better than printed packaging and offers much more real estate to deliver our brand message and helpful consumer information. And it avoids the cost of installing and operating labeling equipment. The rectangular shape also enhances pallet-load-capacity efficiencies.”

After Pack Expo, Best shipped some sample packages to Kullberg to show his team in Portland. Spartech also provided information about supply options to fit Better Bean’s size and scale requirements and worked with equipment vendors to assist Kullberg in providing the data necessary to collect and assess equipment price quotes.

The 1-Seal solution met many of Better Bean’s criteria. The large 14-oz polypropylene-based tub satisfied customer demand for more product per container. The easy-open, no-inner-membrane seal closure design was more consumer-convenient. The rectangular shape enabled a higher-impact billboard effect. And the in-mold labeling allowed for high-quality graphics to enhance shelf differentiation.

The single-component PP seal/PP lid design creates an ultra-thin, air- and water-tight seam within a short-time, low-temperature sealing window. And the proprietary packaging can be customized for tolerance to hot-fill (around 170º F to 195º F, depending on product) as well as retort/autoclave steam kettle processing temperatures for filled/sealed containers (in the vicinity of 250º F, depending on product).

As Kullberg got further into his exploration of the 1-Seal concept, he liked what he was seeing, he explains. “We could see that the 1-Seal lid would eliminate the expensive manufacturing step of applying both a film lidding material and an overcap. And the ability to eliminate the sealing membrane over the tub mouth would simplify opening the product for consumers. The IML label would eliminate the expensive step of purchasing and operating label application equipment. But we still had a concern about the robustness of the 1-Seal lid. It’s such a new application that we weren’t sure that the 1-Seal could compete with existing lidding options in terms of strength and durability.”

To alleviate Better Bean’s concerns about the durability of the system, the Spartech Packaging team, led by Zach Muscato, packaging support engineer, with Better Bean staffers participating, conducted a series of package integrity tests to prove the technology’s robustness. The tests gauged hot-fill performance, seal strength, and shipping performance. All test results exceeded expectations.

Kullberg notes, “We conducted Haug testing of seal integrity and found its burst strength was 20 inches mercury, significantly out-performing a number of packages used by other manufacturers.”

Pulling the packaging plan together

Having determined to go with the 1-Seal system, Better Bean then had to make some other packaging decisions. They chose 14 Hands, a Portland-based design and re-branding firm, to create colorful, eye-catching packaging graphics to achieve the desired billboard effect. And they selected Packline West Inc. for the fully automatic rotary fill/seal/cap equipment (Model NB-070) that cycles at output rates from 40-80 per minute.

In March 2012, seven months after first seeing the 1-Seal system at Pack Expo, The Better Bean Company launched its repackaged gourmet refrigerated fresh beans in 14-oz resealable tubs. The product is filled at 90 degrees Celsius (194º F), and estimated refrigerated shelf life of the sealed-tub beans is eight weeks.

The packaging weighs 1.5-oz, but it reduces the amount of plastic by 12.27% and eliminates the paper labels and adhesives used on the old packaging. Environmental impact modeling using Sustainable Minds software shows a 21% improvement in the overall environmental impact of the new packaging and a 16% improvement in the carbon footprint.

In summary, Kullberg says, “Our goal for the re-brand was to maximize sales by maximizing consumer affinity to our brand, while minimizing marketing costs. The Spartech 1-Seal packaging was central to our re-branding process. We’re excited to be the first using it.”

The Better Bean Company application of Spartech’s 1-Seal packaging garnered the “most innovative” award in the Society of the Plastic Industry’s International Plastics Design Competition at the National Plastics Exposition (NPE 2012). Spartech has the exclusive license to sell the 1-Seal packaging system in the U.S. market.