AG Hair Cosmetics has been a long-standing salon-only producer of hair care products from its Burnaby, British Columbia, Canada, plant. When the company began to develop several new therapeutic hair products, it originally planned to add them to the existing AG line, using its proprietary packaging.

When AG took the packaging project to Dossiercreative, its design firm in Vancouver, it became obvious to both parties that the new formulations were so different they would need a whole different packaging and marketing approach.

“For the new products, we found so many fascinating ingredients that were both unique and expensive, it would have been hard to fold these products in our AG product line,” says Lotte Davis, co-owner of both AG and iv cosmeceuticals. “After talking with the designers, we realized these products deserved a whole new brand and product category.”

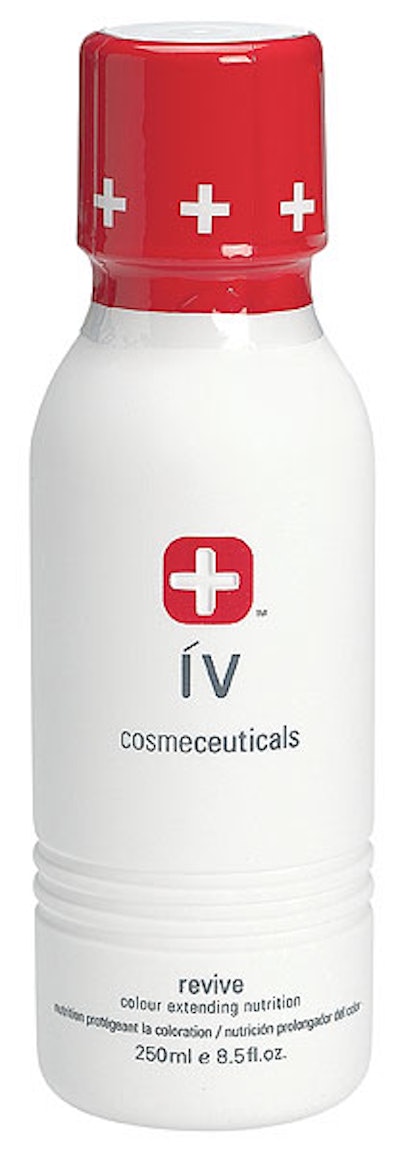

Don Chisholm, creative director at Dossiercreative, says his firm came up with several presentations, all but one based on AG’s private-mold bottle, which was the original plan. “However, we also suggested one ‘out-of-the-box’ idea, which is the basic bottle they’re now using,” he says. “We developed that packaging to emphasize the medical aspects of the products, in essence the ‘first-aid’ genre. At the time, we had a different brand name for the line, but we later discovered some trademark issues. That’s when we switched to ‘iv’ for intense vitalization.”

The ingredients for the new line are often herbals, Davis says, that have been used in a plant form for hundreds of years. “That’s why we call them cosmeceuticals,” she adds. “Although that term is common in skin care, it’s relatively new for hair care products that marry cosmetics and pharmaceuticals. That’s why the design company came up with the soft-touch bottle that’s now proprietary to our line.”

Top-quality presentation

The goal, says Chisholm, was to mimic a medical bottle. “Because these products are sold in a closed environment—the salons—we could be much more dramatic in our presentation,” he adds. Perhaps the most interesting—just becoming available early this year—is the dispensary stand with two hanging intravenous-feeding bags. “We think the dispensary stand really communicates the medical revitalization benefits of the product line,” he enthuses.

Because the presentation had to say “medical and cosmetic,” the bottle shape suggests the pharmacy side, while the use of a soft-touch finish on the outside helps reinforce the cosmetics factor.

The design firm suggested TricorBraun for the bottle distributor because of past experience. In the end, TricorBraun Engineering built the tooling for the bottles, and its International Group built tooling for the friction-fit overcap. The tooling for the overcap, says Maurice Borras, an account manager with Tricor, employs a textured finish “to give them a soft-touch feel” to match those of the bottles.

All 8-oz bottles are fitted with a drip-free Zelvalve from Zeller in Germany. Tricor, says Borras, who handled the iv project, is a premier distributor for Zeller.

Coex for production

The blow molder for iv’s bottles is Precision Blow Molding, and its decorating division handles bottle printing. “This is a coextruded bottle,” says Bob Bhagat, president, “using a medium-density polyethylene inside with a skin layer of the polypropylene-based soft-touch resin.” He declined to identify the source.

The company got into coextrusion about three years ago, and iv’s bottle is produced on a Bekum molder outfitted with a coextrusion head from W. Muller that Precision acquired about six months ago.

Precision was one of the pioneer decorators using an OMSO Novax ultraviolet screen-printing system. “That’s a state-of-the-art decorating system,” says Tricor’s Borras. “It uses ultraviolet-cured inks in a high-speed, high-quality system with very tight tolerances.”

“We’ve used the printing system for about twelve years,” Bhagat says. “With the use of a coex bottle and the tight registration of printing in the recess on the bottle’s front, it becomes an expensive container,” he says.

“We feel that it’s a very clinical, clean white bottle,” says Davis. “We think the white cross on the red background instantly conveys the medical and therapeutic approach of the products. We believe that the dripless valve is a unique dispensing system that allows the consumer to carefully control the amount of product that’s used.

“In addition, we included the tamper-evident neckband that’s also printed with the white cross on the red background. We felt people were accustomed to seeing a seal on drug products, so the neckband addresses that, too.”

Unlike other AG packs

Because of AG’s closed-loop distribution system, the company doesn’t use a TE device on its 40 AG Hair Cosmetics products. So when it added the iv cosmeceuticals products to its production, the plant added a neckband applicator from Axon to its new production line, according to Gary Chan, director of operations at AG Hair.

“We selected the Axon system because we felt it was the most trouble-free applicator we could find,” Chan says. In addition, the plant added a new filler from Inline Filling Systems and created the plant’s fifth filling line to handle the production increases created by the addition of the iv products line.

The heat-shrinkable neckbands are supplied by Japak Industries. The printed bands are manufactured and converted in Taiwan, Chan says, and imported by Japak.

Not only are the iv packages carefully selected to enhance the new line’s medical-pharmaceutical image, the same is true for the outlets that the new line is offered to, says Davis.

“We’re targeting only high-end salons for this new line. After all, these products will sell for about double the price of other salon hair care products,” Davis says. “So we sat down with our distributors to identify specific salons in every market, and we offered them exclusivity for a certain period of time. Actually, this is a big selling feature for the selected salons, because there are so many salon brands available. After all, the price points for these products are restrictive to many salons. It’s unlikely that a woman will go into a salon for an eight-dollar haircut and then buy a $22 bottle of shampoo.”

The prices, Davis says, are largely driven by the costs of the unusual ingredients. But she adds that those prices allow the manufacturer to use more premium-priced packaging components as well.

Coex tubes

Although the bottles and the decorating win much of the line’s focus, some of the new products are filled into tubes and still others in jars. Tricor sources the tubes from CCL Plastics, while the pomade jars are manufactured and decorated in the Far East. All are filled in the AG plant.

The tubes are two-layer coextrusions of low-density polyethylene, according to Marie Ditchfield of CCL Plastics. Each layer uses a concentration of a pearlized ivory colorant from Clariant.

“Unlike the blow molders, we’re not using two layers so we can use less colorant,” she tells Packaging World. “In this case, the customer wanted the same color on the inside and the outside. We’re trying to meet the customer’s idea of what these tubes should look like. For this project, they showed us the bottle and asked us to match the look with the tube. For this tube, we use a higher percentage of color to resin than the standard.

“By using two layers we get a better concentration of the color, and it masks any extrusion lines or watermarks on the tubes. It also makes them more opaque.”

For CCL, production of the tubes is done in two steps, one for coextrusion with the colorant. In the other step, the company applies a closure from Seaquist, applies a matte finish coating, and decorates the tubes in two colors via offset printing—with very tight registration, Ditchfield points out. The matte coating gives the tube more of the look of the soft-touch finish of the bottle.

Lots of testing, training

Because of the unusual ingredients, Davis says that in-salon training is more rigorous than with more conventional hair care products. “For our AG products, our training consists of styling and cutting techniques. With the iv products, we train the salon people about the ingredients and how unique they are. We’ve found that beauticians enjoy learning about the technical part of these products so they can explain the efficacy of these products to their clients. We help them to pronounce the names of some of our exotic ingredients.”

Davis says the company did considerable testing of these products upfront, “because we needed to be confident about their efficacy.” This line, she adds, creates a new category of products in an already saturated market.

“The packaging really helped create excitement in the salons and by distributors. These days, you can’t get your foot in the door without strong packaging,” Davis adds. She also reports that Tricor supplies a small 1-oz sample bottle that was very difficult to decorate. “We wanted the salons to have a way for the customer to smell the product, so the 1-oz is a trial size. We display it in a white medical tin, like a first-aid kit.”

The medical theme is reinforced when the products are first introduced to a salon. “We use models dressed up like nurses, and we use hospital admitting wristbands for customers,” she adds. “The reaction has been extremely positive. Every salon we’ve contacted has been eager to add this line, and we’re seeing healthy repeat orders, too.”