HCP: Thank you, Chris, for joining me today. Chris Chudek has 10 years' experience in pharmaceutical packaging development, specifically with combination products and med device. He has worked in various companies, including Pfizer, so with that, Chris, feel free to take it away with a little bit more about who you are.

Chris Chudek: Sure, thanks for having me, by the way, I appreciate that. My entire career has been in product development. I have, like you mentioned, 10 years of development experience with the combination products and medical devices, specifically in pharmaceutical R&D environments. And I would focus typically on engineering, testing and documentation, within that space. I also have a background in human factors as a certified usability analyst, and by combining those two things, it gave me the opportunity to actually work on pharmaceutical labeling and then finally, pharmaceutical packaging. Which is what we're here to talk about today, and I feel like I have some, hopefully some helpful insights and thoughts that, maybe, could be considered for others as well.

HCP: Yeah, exactly, so why don't we just kick off, you know, you mentioned several things, the importance of packaging within medical device, pharma products, obviously adherence, usability, if we can't use it, we can't adhere to it. So there's, you know, a whole slew of importance when you talk about the packaging and labeling of these products. So why don't we just kind of talk a little bit about that.

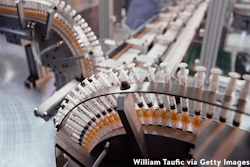

Chris Chudek: Sure. I wanted to start off just by talking about the combination products just in general, because of my experience there. I mean, to me, the most critical part of that is accurately delivering the dose to patients. I mean, without that, it doesn't really matter what it does. And I think that, you know, when you start out with that, and then it goes into the packaging portion. So, what is the packaging look like relative to the device?

And I think protecting the drug itself and then protecting the device, And how that all kind of comes together, I think is the, to me is the most important part. when you, after you put those two together, I think confidence in packaging is really important.

In other words, if somebody receives a package and it's damaged or broken, things like that, you're not sure if it's, if it's going to work properly or there could be, internal damage and spillage of the drug, or you, you really don't know what's going on inside sometimes.

So I think instilling that confidence is important along with the protection part. So when, that's what I look for in, you know, as a high level in packaging in general.

HCP: And then we talk about the human factor side, and this, you know, for combination products and pharmaceutical or med device, I mean human factors is so essential, you know, people have to know how to use it, they have to be comfortable using it, and maybe even administering it on to someone else. So let's talk about a little bit about, you know, how human factors are, brought into the development stage.

Chris Chudek: Sure. I think the idea of the life cycle of the user interaction with packaging is important. So, starting all the way from the initial opening or the receiving, I should say, of the packaging itself, and then how you open it and how you work with it, take out the components all the way down to the disposal of the packaging. So really getting a good feel for that entire life cycle, I think is a, is a great way to start to really try to understand it a little bit better. I think you, you started to mention it. I think the, when, when somebody initially, looks at the packaging, are they able to understand how to open it? Is it clearly, a marked or are there features on there or graphics that say this is how you open the packaging, or is it just very confusing and they just don't know how to do it properly.

Second is, do they have the ability to open it? So, are they able to, like sometimes clamshell, packaging it's very difficult to open. So, is it, is it easy for them to open? Can they understand how to do it properly without getting injured? I definitely like focusing on those areas. And then finally, the idea of multi multi-dose combination products. So when you, when you have multi-dose versions, The packaging actually becomes more of a storage container. So, when you're actually working with these different pieces and parts, you know, the, the device itself, perhaps a drug vial, multiple syringes, package insert, how all those work together, for the initial use, they have to be kind of replaced back into the packaging, just to make sure all the pieces stay together. And having that, you know, resolved and understood is important for that part of the, Human factors part as well.

HCP: Do you have a good example of a multi-dose product?

Chris Chudek: Again, I've seen, the different, examples that I've used. I've actually had like a drug vial with, multiple syringes, depending on how it was going to be used. And, yeah, so I've seen that, and then you have to insert the package insert inside there as well. And, and having, you know, Trying to figure out how they fit into the packaging is one thing, but how they can be replaced back into the packaging is the, the real challenge. And so that's where the development cycle kind of goes through testing and, figuring out how that, how that best can be used to make it easier for the, for the user as they interact with it.

HCP: Sure. And when you say testing, is that like a focus group of people, you know, various people of ages or dexterity, you know, limitations or such, trying to figure out how to use this or, you know, showing them how can they repeat it back, that type of thing?

Chris Chudek: Right. And this is, this is where, packaging really needs to be as intuitive as possible. So if you give somebody a packaging and, you talked about the like human factors testing formatives, when you give them the packaging, can they figure it out, without, without having, you know, formal instructions? I know the device itself has, you know, instructions, typically instructions for use, but how they work out the, the packaging part, that's, unless it's clearly defined on the packaging itself with, like I said, it's graphics or features or tabs. I think that's where a lot of it, the understanding and clarity needs to come from you have to really, you know, carefully consider those, prior to that process.

HCP: Yeah, and I, I know I'm not the only one who kind of just chooses not to read the directions and just starts trying to figure it out and hope for the best, but I'm sure with some stuff that's probably not the best idea.

Chris Chudek: Right, right.

HCP: So kind of, you know, evolving the question for designing for adherence. So we've talked about usability, which they do go hand in hand, you know, we're not using it without, we're not adhering to it without being able to use it. But are there any specific things that companies look to design for adherence specifically?

Chris Chudek: Well, it, to me the, the compliance part is all closely related to the functional testing and how that works. So how you trans, you know, packaging just in general, how you transport from one place to another and, and understanding that, that methodology and, and where that, where that comes from. And this is where clarifying the, the idea of protecting the drug itself, whether it's, you know, if there's thermal conditions that need to be addressed or light sensitivity, making sure it's the drug is, you know, sufficiently protected. And then you have the device itself. And when I would work with devices in the packaging, you need to start off with conditioning. Whether it's sterilization or, again, thermal conditioning, storage, all those are kind of precursors to the more robust ASTM 4169, drop in vibration testing, which is one of the key features in, ensuring that packaging is appropriate, for the, the marketplace.

HCP: OK, awesome. So, combination product development, which is, you know, your background or your specialty, as I think you said, I'm sure there's a lot of teams involved in the process of this development. It can't just be you, right, or your team. So, you know, how many, how many groups or teams, you know, weigh in on decision making?

Chris Chudek: Right. I think it starts off with marketing, typically marketing has an idea of what they might want to use. It can be, you know, bulk pack or, clamshell tray, or, SBS carton. It just depends on what they're, what they're looking for. And then we, we talked about the human factors and the medical team getting involved with the user experience and getting that just right.

And then the other people obviously program and project management, making sure that you can get that into the cycle, at an appropriate time, and appropriate cost, and then the manufacturing and production side where you're trying to figure out how to, how to make the cartons, make the trays, and then put all the different components inside there and again get that ready for, for shipping. but to me the, maybe it's because of my experience here, but that relationship between, the device team and the packaging team is probably the most important one of all. when I, when I think about that, that, that, again, that relationship kind of establishes everything and getting that communication just right is, is probably the most important step in the process.

HCP: OK, yeah. So factoring in, you know, packaging before product development, cause there's product development, right, and then there's package development, are there best practice best practices for either or, or, you know, thinking of it differently like what comes first, I guess, the product or the packaging, or do you start at the same time, you know, with product development.

Chris Chudek: It would be really nice if you could start those at a at a very similar time frame. I know that's a lot to ask, but sometimes I think how that, that works is important, if And I bring this up because, if you have a very robust device that's really sturdy, that you feel confident with, I think it, it allows for a much more simplistic type of packaging, where it's, basically put into, again, like a carton or, or something along those lines. But it's when you have fragile devices where the, the features have maybe some flexibility or the, the tamper evident feature is very fragile. That's when you need a lot more sophisticated packaging. And if you don't know that early on, it, it makes very challenging at the tail end.

You're constantly scrambling and trying to make things come together.

So, I think getting a good feel for what the requirements are going to be early on from a packaging perspective really helps to be able to tie those the two work streams together, the device and the, and the packaging part.

HCP: Sure, yeah, I understand, you know, depending on the kind of product or device and, you know the sort of packaging then it would obviously change depending on the level of protection required.

So, you know, let's talk a little bit of, I guess about if you have any final words of advice for young people starting out, you know, maybe just out of college, starting their careers in medical device development or pharmaceutical packaging development, you know, how do they get started or, you know, what are some, you know, takeaways that you can offer as they start their career?

Chris Chudek: I think one of the, one of the nice things would be is to try to get in, get yourself involved in the packaging process as early as possible. So, if you're on the packaging team and you're assigned to a program or a project, try to get involved as soon as you can. Learn about what the, what you're going to be packaging, how does it look, how does it work, getting a feel for the needs of not only the marketing team. but the human factors team as well, how, how that looks and how that could, come together because the you, you don't wanna have to be forced into awkward conversations and, resolutions to problems later on down the road. If you can avoid that, I think that's, that's actually a a important thing to, to take away from that. but I will say this too, I think enjoying the process, I have to tell you, because I've been in, the R&D environment for a long time, it's actually really enjoyable and pleasant. I know it can be challenging at sometimes, but it's a fun experience and, it's definitely worth the, worth the effort for sure.

HCP: Do you have any failures that you can loosely talk about that, you know, in the R&D process and maybe it was, just we couldn't figure out how to package it properly or we thought we did, and then you're like, oh no, like it's completely incompatible. Any, you know, kind of examples you can share and how you work around it.

Chris Chudek: Yep, I know I talked about that. This was a marketing request. They felt like we could go with basically a bulk pack for a particular syringe. And what happened was in the, preliminary functional testing, it did not do well. Not only was the packaging, damaged, but the device was damaged as well, so it was a, it was not a good situation at all. And so, if we had known about that earlier, we probably could have addressed it in a different way. But as it ends up, we, we actually were successful, it became a clamshell package that was, that actually worked. It survived the, the 4169 testing. So it made, it made sense.

It was actually a comfortable packaging from a user perspective as well. So it all worked out, but boy, having information of knowing what the marketing needs were and comparing those to what it, what it was, this is why as soon as you can get involved, it's so much easier to make all that come together.

HCP: Yeah, that, that makes sense, because no one wants to rework a project in any industry, right? So, yeah. Awesome, well, thank you, Chris, for your time today.

Chris Chudek: No, I really appreciate the opportunity to talk. Thank you so much.