Our lifestyle is becoming more and more individual, agile and independent. This also influences the way we view and use medication. Self-administration is trending wherever possible, giving patients maximum autonomy and flexibility. While self-administration of insulin is already state-of-the-art in diabetes care, it is also advancing in some areas of oncology or hormone therapy.

Along with the globally increasing number of diabetes patients, the market for insulin is growing continuously—and with it the demand for pens and other injection aids. The growing demand for pens and auto-injectors calls for flexible assembly machines that allow for a fast time-to-market of a large number of different products.

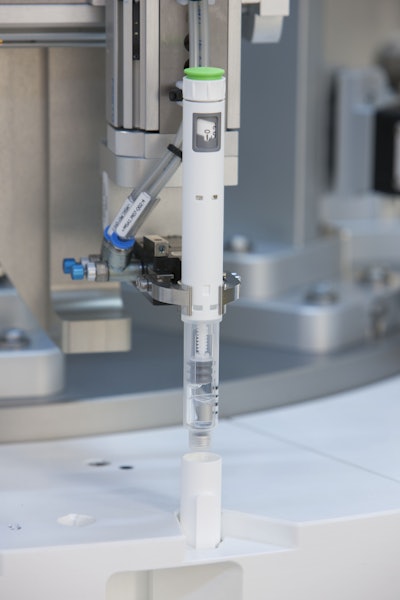

Pens are currently the most widely adopted system for insulin injection, mainly due to their ease of use. Instead of using insulin in vials, which requires a syringe to inject the fluid and a considerable amount of experience in dosing and syringe injection, pens are loaded with insulin-filled glass cartridges. The rear end of the cartridge is closed with a rubber stopper, while the front end is closed by an aluminum cap with a puncture membrane, into which a needle can be inserted. At the top, the device is equipped with a dosing mechanism, which can easily be turned to adjust the amount of insulin that needs to be injected.

Easy and safe handling of the pens is the most important criterion for patients, as it gives them more flexibility in their daily life. Thanks to today’s self-monitoring of blood glucose, patients are able to calculate their individual insulin dose. Pens are used as multiple application systems, usually containing insulin for several units. Depending on the individual requirements, one pen can last for up to a week; only the needles must be replaced for hygienic reasons. Due to the efficient design, pens can be taken anywhere conveniently, and can be applied without much effort, even by kids.