A recognized leader in retail trends and sustainability issues, Walmart is poised to further drive the use of patient-compliant calendarized packaging in the U.S. with its December 2012 launch of paperboard-based ecoslide-RX® packs supplied by Keystone Folding Box Co.

The new portable, calendar-style prescription packs, which aim to increase patient adherence to drug regimens, are now rolling out at nearly 4,600 Walmart retail pharmacies across the U.S., initially for 40 different items, with plans to use the packs for another 35 to 40 items by early 2013. Walmart will employ the ecoslide-RX® packs for prescriptions as an additional package configuration, joining traditional amber vials and caps, as well as other calendar-style packs made of other paperboard and plastics.

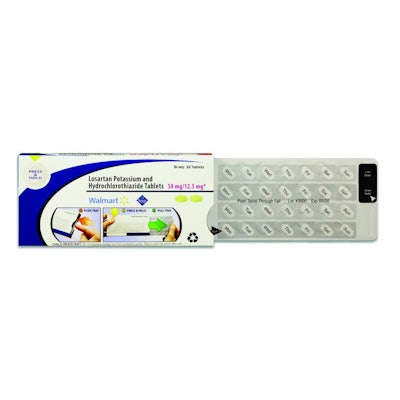

The pack measures 6 in. W x nearly 3 in. H x nearly 1⁄2 in. deep. Keystone offset-prints the 18-pt paperboard outer sleeve in five colors. On the front panel is Walmart information, opening instructions, drug details, and photos of the specific drug, as well as the child-resistant release button that instructs the consumer to press and hold a corner tab to slide open the product-containing blister within the paperboard sleeve. The blister materials are supplied separately.

For Bentonville, AR-based Walmart, improved patient adherence will yield economic, supply chain, and sustainability advantages. “The biggest opportunity that we see for consumers in a compliance pack is the ability to help them adhere to a medical regimen,” says Ron Sasine, Walmart’s senior director of packaging for private brands. “So often, what we see in a treatment pattern is that the patient is very diligent at the outset of that regimen. But we start to see a drop-off or a lack of adherence weeks and months later. So the real beauty of this type of a pack is it provides a physical printed reminder and an opportunity for consumers to see whether a dose for a certain day has been taken or not. It really gives—and we have seen the medical literature that supports this—a strong uptick in patient adherence to medical dosage.”

Jodie Cartwright, senior pharmaceutical buyer at Walmart, adds, “Ron speaks about the medical journals and articles that have been published around compliance. Most recently there have been a couple of white paper publications that Walmart had great interest in, one of which was from the manufacturer of the brand Diovan [a Novartis blood pressure medicine] that Walmart partnered with. Results of the initiative far exceeded our expectations, demonstrating if the patient looks every day to see that he or she has taken the medication, he or she ends up getting the prescription refilled on time and taking the medication all year long as prescribed.”

Greater adherence improves patient outcomes and ultimately reduces healthcare costs across the supply chain. That appeals to Walmart on many levels, fitting into what Cartwright refers to as the company’s “one-stop-shop” strategy. “For us, probably the most unique thing that we have for our shoppers is that we are considered a one-stop shop. Customers are able to come into our store, pick up their prescription, get milk and healthy food, and buy fitness and exercise equipment and related apparel.”

The evaluation process

Walmart continually evaluates packaging and supply chain options as part of its internal process to benefit customers and improve internal operations. The move to add the ecoslide-RX® pack stems from that ever-evolving evaluation process.

Says Sasine, “We were approached by Keystone and were interested in their ecoslide-RX® development as a potential alternative to broaden what was being done with calendarized packaging for medications. We began conversations with them about how to make the most effective calendar pack, primarily from child-resistance and cost standpoints. We began a development process with them that has spanned more than a year and a half. We’ve met at pharmaceutical and packaging meetings and watched their product development. They gave us regular updates so we could keep track.”

Sustainability factors

Prescription packaging determinations are made by Walmart based upon what makes sense for a particular drug. The ecoslide-RX® calendar pack is tailor-made for once-a-day, 30-day doses, as opposed to scripts that are taken multiple times per day or in different dosage amounts.

Ecoslide-RX® also fits into Walmart’s sustainability initiatives. Sasine explains: “In any type of carded blister, what we are doing is replacing plastic resin with recyclable paperboard. So for the consumer, there’s a greater possibility of disposing that outer sleeve in a recycle stream rather than in a waste-to-landfill stream. That’s a big benefit from our point of view. Of course, there will be that inner chamber of the blister itself, but that’s a far smaller component than the overall outer shell.”

What the consumer does with the package becomes key in this process. Rigid plastics, too, are recyclable, but if the consumer discards either package in the garbage, the recyclable factor becomes mute. Says Sasine, “It corresponds to the local municipality and the availability of different recycling streams for paperboard and plastics.”

That said, Walmart responds to consumer preferences for sustainable alternatives, with paperboard viewed favorably by many consumers. As a result, says Cartwright, “We work with manufacturers to transition medication packs into more sustainable paperboard materials.”

Sasine notes another matter that comes into play in the sustainability discussion: “In looking at pharmaceutical packaging, one of the issues that arises is medication residue left in a bottle after a script has been taken. Sometimes people may forget to take all their medication, so some pills may be left over, and the patient may not know what to do with them. With a calendar-style pack, the medication tends to get used in its entirety so that the pack can get disposed of without leaving behind any additional bits of pill that you might find in a medicine bottle. That means more packaging materials can be sent to a recycler than to the waste hauler.”

Following the process

Asked if Walmart did consumer focus-group testing before selecting the ecoslide-RX® pack, Sasine notes, “It is interesting about focus groups—the most important testing that’s conducted on any pharmaceutical pack is child-resistance testing. We had testing conducted by the pharmaceutical manufacturers on all of the calendar packs before we would agree to bring them in. Regarding consumer testing, we rolled out our first consumer calendarized packs about six years ago, so we have a good record of consumer observations and helpful comments that we have been able to work from as we designed this with our suppliers. So it’s been less an issue of consumer testing and more an issue of direct consumer feedback from the steps that they have already seen in the market.”

“We use a photographic pictogram of how to open the package because at the end of the day this may be the first time a consumer has seen a pack like this,” explains Ward Smith, Keystone’s director of marketing and sales. “It borrows from the concept of icons you might see on a computer, tablet, or electronic device.”

Printed on the back panel are regulatory details, drug name, strength, and more photographs of the product. “The photographs offer visual cues for the patient, the pharmacist, and the technician to check that the pills inside the package match the photograph on the box,” explains Smith.

Keystone runs the printed sleeve material through separate folding and gluing machinery from Bobst. The finished sleeves, plastic blister-forming web, and foil lidding materials are supplied by other vendors. All three components are sent to Legacy Pharmaceutical Packaging where they’re packaged on thermoform/fill/seal equipment. Medication manufacturers typically send Legacy solid-dose pharmaceuticals in bulk quantities for repackaging into the ecoslide-RX® packs.

Tabs on the outer carton instruct patients how to open the pack and slide out the calendared blister. “There’s a security mechanism built to deter children from accessing the medication,” says Sasine of the pack, which achieves a F=1 child-resistance rating and offers customer safety and ease of use.

Prescription packaging evolves

Since it began adding pharmacies in its retail stores in the 1970s, Walmart has relied primarily on traditional amber vials and caps for prescription packaging. That began to change in recent years as consumers became familiar with calendarized blister packs for medications used to treat influenza and bacterial infections.

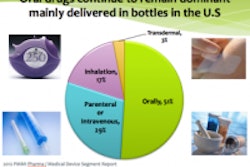

Sasine says, “Carded blister packaging for pharmaceuticals has been a trend in Europe for years. In the U.S., we are moving toward greater use of this style of packaging and have added the days of the week on the blister packaging, thus calendarizing the package.”

One school of thought suggests that employing a calendar pack frees up pharmacists from filling scripts at the pharmacy, allowing them more time to engage consumers. Cartwright says Walmart has seen some of that, but believes such packaging “helps us bridge that gap with education between the pharmacist and the patient. So, really it’s a matter of talking to the patient about why we are using this pack, explaining that it’s something that Walmart feels strongly about, and that we are doing this for the patient to help them remember to take their medication.”

Looking forward

In the future, Walmart will continue to utilize amber vials and caps and other alternative calendarized packages in its pharmacies to give it the flexibility it needs. “We understand and we see that across the pharmacy and across the rest of the store for that matter there is a need for options and flexibility for our consumers so that the patients have what best serves their needs. It’s about the dosage and what the physician is prescribing,” adds Cartwright. “The goal with all the calendarized packs is to try to get the patient to adhere to the medication prescribed by their physician. That will drive some traffic for us but, first and foremost, we have our patients’ best interests at heart.”

The calendar packs also fit into Walmart’s supply chain. Says Sasine, “We have accomplished a great deal of efficiency by the way we’ve integrated with calendar-pack manufacturers. So they know the shipments that will be coming in from our behalf from the drug manufacturers. We coordinate with them, delivering into our pharmaceutical distribution centers. We are very tightly integrated backwards into their supply chain so that what they are seeing is a very efficient and seamless operation based on the way they have to manufacture each of the components and fill those components.”

So what are the financial implications of moving to ecoslide-RX® as compared to maybe other calendar packs? “Without getting into too many specifics,” Sasine says, “I want to point to Walmart’s mission statement to save people money so they can live better. This is one of those areas where we think both things happen at the same time, that we are providing cost savings efforts to them. At the same time, we are helping to encourage them to take medications as prescribed so that they can maintain that ‘live better’ part of the equation. It’s nice by moving or by transitioning packaging from plastic packaging of any type to a package that involves more paperboard because there does tend to be a cost savings in that exchange. It’s one that has been significant enough to keep us moving forward in this direction.”

Ultimately, Sasine hopes to see an integration of packaging with information systems. “I don’t know what the interface will be or how it will happen,” he says, “but I can picture a time where a patient’s smartphone will be able to read information from a package to help track their own performance and communicate upstream with the medical professionals’ information systems.

“I think we are getting very close to that. I have seen prototypes that do some very interesting things, but the ability to integrate back from the moment of taking medication to healthcare results and providing analysis to the healthcare provider, to the insurer, or to the other third-party payer in the system will become something that drives a good deal of new innovation.

“If you look at the news stories today talking about healthcare outcomes, and the possibility for packaging to impact those outcomes by being more relevant, it becomes clear that there is big potential for a positive impact for us at Walmart.”

Cartwright says, “We feel strongly that the addition of the ecoslide-RX® package is the right thing to do for patients. We don’t plan these packs to completely replace other packaging formats, but to use them as an alternative. We are working with manufacturers to introduce this process and to educate them on the calendarized pack. As new studies have been published, we constantly have conversations with our drug manufacturers to start this process with the calendarized packs, not just as something for Walmart, but also we are really trying to get it out there in the industry.”