Recycled expanded polystyrene containers make for a sustainable packaging solution for shipments of sanofi pasteur's liquid and freeze-dried vaccines.

EPS, which is often criticized for its environmental impact, is proving to be a sound material choice, according to Bill Tarabek, director, U.S. distribution for sanofi pasteur, the Lyon, France-based vaccines division of the Sanofi-Aventis Group. “EPS is not environmentally unfriendly—it's just the opposite,” Tarabek contends.

“Unlike other material such as paper, EPS does not degrade and will not leach any substances into groundwater, nor will it form harmful gases,” he adds. “So although EPS can be safely disposed in today's landfills, sanofi pasteur developed a Return and Recycle Program for our customers who prefer to recycle. Expanded polystyrene is 100-percent recyclable. To be clear, we are not talking about everyday packing peanuts, these are white shipping containers.”

Since January 2008, sanofi pasteur has offered its U.S. customers a prepaid mail-back recycling program that works through a partnership with the Alliance of Foam Packaging Recyclers. AFPR was founded in 1991 to develop an industry-based collection infrastructure.

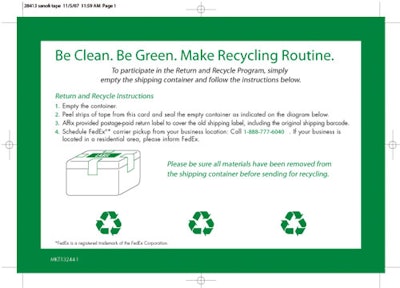

Sanofi pasteur's customers—physician's offices, hospitals, and healthcare providers—open the EPS shipper, which contains refrigerated and/or frozen gel packs to maintain the products within the necessary temperature range. The packaged vials are removed from a polyethylene bag. sanofi pasteur supplies tape strips and a recyclable shipping label to customers who then apply the label to the box, tape the lid to the box, and give it to their courier for shipment to a recycler.

AFPR's deputy director, Virginia Lyle, credits JML Recycling, a division of Sebright Products, for working with sanofi pasteur—and some additional pharmaceutical companies—to make their cooler recycling program work. “The company created innovative ways to handle the container labels [that could otherwise impede the recycling process],” she says.

Expanded EPS use pleases customers

Although sanofi pasteur still uses limited quantities of polyurethane containers. Says Tarabek, “Polyurethane is not recyclable. We continue to rely more on EPS for as many of our boxes as we can.” He says the company recently completed a project that will employ tens of thousands of EPS containers for a temperature-sensitive product that historically shipped in polyurethane boxes. “With the help of our shipping container vendor, we developed a recyclable EPS solution that will make our customers happy,” he says. “The fact that we took an entire product line and moved it from polyurethane to EPS also provided an outcome that we like, as it will reduce our packaging and freight costs.”

Tarabek says sanofi pasteur uses four sizes of EPS containers right now that handle anywhere from one vaccine vial to 200 vials. These temperature-sensitive products are shipped via either one- or two-day small parcel service from the company's three U.S. distribution centers.

“About 75 to 90 percent of our shipments are in EPS boxes. In the past, the polyurethane containers posed challenges for our customers because they are bulky to dispose in their regular trash pickups,” Tarabek explains.

“Physicians and healthcare practitioners, like the rest of the country, are becoming more and more attuned to the environment and the significance of the actions they take. For years, sanofi pasteur has worked hard on sustainability initiatives, in our manufacturing processes, how we use our water, and in the use of packaging materials, where we try to improve our stewardship of the environment. Our customers think it's important, and we believe that there is a competitive advantage to being green,” he says.

In the first year of the program, more than 180,000 containers were returned for recycling. Last year the program grew by 10% with uptake exceeding 200,000 containers.

Asked about the economics of the move to recyclable EPS containers, Tarabek admits, “Our recycling program is not cost-neutral. There is a cost to the company, but management believes in being green. It helps improve our customer relationship and loyalty because it helps solve a problem for our customers, who no longer have to pay for disposal of the former containers, or to send them to a landfill. They get a good feeling that 'this is going to a recycling center, it's easier to get rid of, and I just have to put a label on it and hand it to my driver the next day.'”