This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Aptar CSP Technologies, part of AptarGroup, Inc. and a distributor in active material science, announced that it has developed a dual-active material science technology engineered to simultaneously control moisture and oxygen. This technology is designed to provide a singular solution to address these degradation drivers for pharmaceutical drugs, including oral solid dose glucagon-like peptide-1 (GLP-1), medical devices and more.

This solution marks a material science breakthrough in the pharmaceutical industry, extending Aptar CSP Technologies’ 3-Phase Activ-Polymer technology into use cases where a combination of humidity and oxidation can compromise the efficacy, safety, and shelf life of sensitive oral solid dose drugs, medical devices, implantable mesh devices, microarray patches and transdermal delivery systems.

“This launch reflects years of development, engineering excellence, and a deep understanding of our customers’ most pressing stability challenges,” says Badre Hammond, Vice President Commercial Operations and General Manager, Aptar CSP Technologies. “There has never been a singular, standalone active material aimed at protecting against both oxidation and moisture-related degradation at this level of precision across multiple platforms. We’re proud to offer a solution that is not only scientifically differentiated but can also be commercially validated."

Aptar CSP’s dual-active technology can be customized for a range of product formats and development stages, from early R&D to commercial launch. The technology can help support regulatory compliance and product protection across a variety of formats, aimed at helping companies meet strict International Council for Harmonization (ICH) stability requirements while maintaining performance and integrity of sensitive drug or device components.

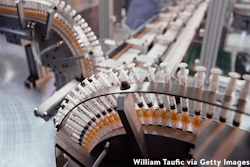

In addition to protection technology for oral solid dose GLP-1, Aptar also offers a range of high-quality elastomeric components for GLP-1 drug products, including plungers and rigid needle shields. Pharmaceutical companies have validated Aptar’s elastomeric components and are partnering with Aptar to develop injectable solutions for GLP-1. By combining digital and Aptar’s patient services, Aptar offers fully integrated solutions, which helps drug manufacturers create differentiated drug delivery systems and enhance patient experiences for GLP-1 and other applications.