Successful businesses listen—and respond—to their customers.

Clearly that’s exemplified by Hardy Process Solutions, a Roper Technologies company and provider of process weighing and packaging solutions. Hardy believes that weighing machinery should be easy to integrate, maintain, and operate, delivering the lowest cost to own for its customers.

A good example of this is the Hardy Dynamic Checkweigher line, available in S Series (Small), I Series (Intermediate), C Series (Chainweigher) and Dynamic L Series (Large). Introduced in March 2017, the Dynamic units provide fast, precise determination of an object’s weight while that object is in motion.

The checkweighers diagnose and reduce overfill rates through process optimization with filling machines. They can be integrated into a customer’s factory control system via Rockwell Automation’s FactoryTalk® analytics program. Why did they select Rockwell Automation?

“They dominate the North American market, so we selected components that our customers are familiar with and can easily integrate into their existing manufacturing systems,” explains Timothy Norman, Hardy’s Project Management, Business Development. “The components are also available from hundreds of Rockwell distributors throughout North America for easy servicing.”

Three key benefits

Hardy’s Dynamic Checkweigher works in virtually any industry that ships discrete products. For medical applications, the machinery can determine if the contents of a packaged procedure are correct—for example, confirming that the kit contains one catheter, one instruction pack and one accessory pack. In the pharmaceutical industry, the Dynamic can verify that a bottle contains the correct number of pills.

Norman says the Dynamic’s automation and controls systems help make the machine unique through three specific customer benefits:

- Open Source programmability: “We make the machine fit the customer process, not make the customer process fit the machine,” he notes. Because the machine is completely programmable, it permits the addition or subtraction of data output, such as SPC, standard deviation, total overfill, Six Sigma, etc. Also, the Dynamic can be modified for future needs by adding components such as rejecters, indicator lights, blow-off devices and sorters.

- Seamless integration: The machine’s control architecture is made up of 90% Rockwell Automation components; 10% Hardy Process Solutions’ weighing functions; it eliminates the need for “middle-ware” or time-consuming programming that enables the machine to exchange valuable data with a factory control system—right out of the box.

- Off-the-shelf components: The machines are built with non-custom parts that are easy to replace and readily available through multiple sources.

Process load balancing

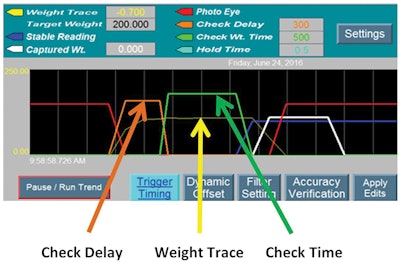

Hardy took a disciplined approach to process load balancing in designing the Dynamic line. Says Norman, “Many process and automation networks are separated from the high bandwidth requirements of SCADA, HMI and Database networks. We used Class 1 or implicit messaging, which is scheduled, using cyclic data. This type of messaging is used for fast, time-sensitive I/O control, including live weight data between our HI 4050CW checkweighing controller and the Rockwell Automation CompactLogix PLC. We are not affected by network saturation or latency with this strategy.”

He believes Hardy is Rockwell’s only weighing partner to achieve Premier Integration Status, considered the highest level of integration with Rockwell Automation CompactLogix® (also ControlLogix® and 1734 POINT I/O systems).

“The combination of Open Source code and making all data tags available, together with Rockwell’s Studio 5000 software, makes integration into existing systems quick and easy,” Norman says. “The Dynamic checkweighing machine appears as an IP-addressable device on a network where all data and controls can be shared or monitored from any place on the network.”

Overall, the Dynamic control system includes the following components:

• HI 4050-CW checkweight controller

• AB 1769-PLC, expandable with spare I/O

• PanelView Plus- IP addressable HMI

• AB Stratix Switch with two spare ports

• AB performance power supply

• UL508-certified panel

• Smart motor drives

What’s next?

When Hardy introduced the Dynamic line early last year, it focused on the North American market, although some inquiries have come from South America. If the machines are introduced in other global markets, says Norman, different control systems could be considered.

Hundreds of installations of Hardy’s check-weighing controller are in use, says Norman, which makes sense given Hardy’s commitment to listening to customer needs. “It was a customer-driven decision to move away from ‘black box’ controls and locked-down firmware. Customers wanted standard components with proprietary components avoided. They also wanted to be able to service machines easily with parts sourced locally.

“Open Source software is evolving as customers’ request unique functions for specific applications.For example, the number and type of data analysis and statistics measured that the machine now produces far surpasses the original release. Machines can be upgraded easily to keep them up to date and to add functionality,” Norman notes.