This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

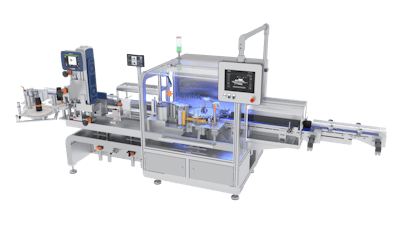

Faster and more aligned with the needs of evolving pharma production lines, the Herma’s updated 132M HC wraparound labeler includes a sophisticated yet simplified new touchscreen HMI to coincide with improved ergonomics and an output ceiling of 600 products/min – a 50% uptick over the previous model.

Designed for vials from 2 ml upwards and any cylindrical container up to 90 mm in diameter, Herma’s 132M HC wraparound labeler offers 24/7 operation and the robustness demanded by the sector’s inherent high batch sizes. Featuring fast, tool-free changeover and electronic position indicators, the unit combines rapid labeling speeds with exacting precision via the company’s Herma 500 label applicator.

For Herma, the reconfiguration the 132M is part of a series of improvements to its machinery range from both an operational and ergonomic perspective. Dubbed Clean Design, the extensive use of stainless steel ensures compliance with the strict GMP hygiene requirements in the pharmaceutical industry.